Disease control on farms depends largely on internal biosecurity. One of the most sensitive areas is the post-weaning phase, where, usually, different ages (batches) coincide even though they are separated into different rooms or compartments. This overlap in ages is what causes certain infections to become endemic, such as PRRS virus infection. In fact, in multi-site systems where the different ages are located in physically separated sites, it is easy for batches to remain negative to infection, and it is not because distance prevents the transmission of diseases by air since there are ventilation systems such as the ones that take in air directly from the outside, that also prevent it. The difference is that distance prevents the sharing of tools and prevents people from moving from one age to another, thus contaminating them.

This transmission of pathogens between batches could be reduced by changing some routine practices. It is common for animals to be checked daily and for those that show signs of disease to be given an injectable antibiotic following the veterinary advice. These materials are usually used for the entire weaning barn. In the best scenario, the needles are changed between rooms, but unfortunately this is not always the case. A well-meaning farmer will inject the sick pig, which is also more likely to be one of the viremic ones, and the virus will pass from one room to the other, generating viral recirculation. This is, in some cases, the reason that virus circulation continues in the weaning phase.

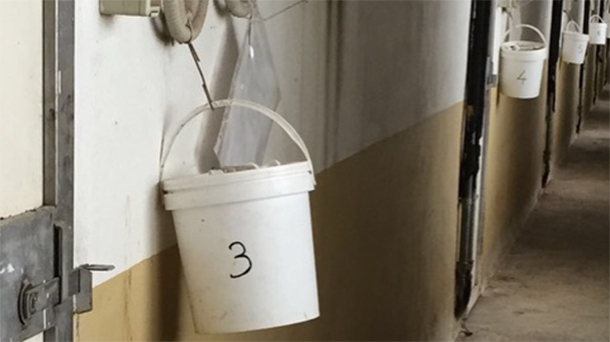

A measure as simple as having one bucket per room or age of pigs, in which specific material is stored, prevents this from happening, improving the internal biosecurity of the farm. This will not only allow us to control local PRRS virus circulation, but also reduce other infections. The buckets can be marked with a specific number or color per room, so that any error is very evident. This measure could be complemented with specific boots and gloves for each room, which even further helps to maintain proper biosecurity, without much effort.