Swine veterinary consultants have the privilege of visiting a wide range of production facilities in their day to day work. The degree of planning and level of investment that goes into the biosecurity of these operations varies dramatically. However, low cost, high impact biosecurity can be practised in any facility.

As our understanding of how infectious disease is transmitted has evolved, we have improved our ability to determine which biosecurity practices are the most important for the prevention of disease entry. Those producers that have experienced a disease outbreak that ruined their profits are the best at acknowledging their biosecurity weaknesses and implementing changes, because they have asked themselves what could have they done differently to prevent the recurrence of the problem.

Following any outbreak, swine veterinarians lead investigations to help understand the most likely route of infection and make recommendations to help answer what went wrong. Their understanding of how pathogens are shed, survive, and how they infect other animals help them to highlight possible biosecurity weak points and recommend biosecurity measurements that can be applied in farms to prevent future disease transmission.

A very good biosecurity report for the swine industry was created in 2010 by the World Organization of Animal Health (OIE) together with the Food and Agriculture Organization of the United Nations (FAO) and the World Bank. In this document, the authors, scientists and veterinarians from all over the world, agreed to define the three main elements of biosecurity as:

- Segregation: or the creation of barriers to limit the potential opportunities for an infected animal (or contaminated material) to enter an uninfected site.

- Cleaning: defined as the process that will remove most of the visible dirt from materials (such us vehicles or equipment) that may enter the farm.

- Disinfection: when properly applied, will inactivate any pathogens still present in materials that have already gone through the cleaning process.

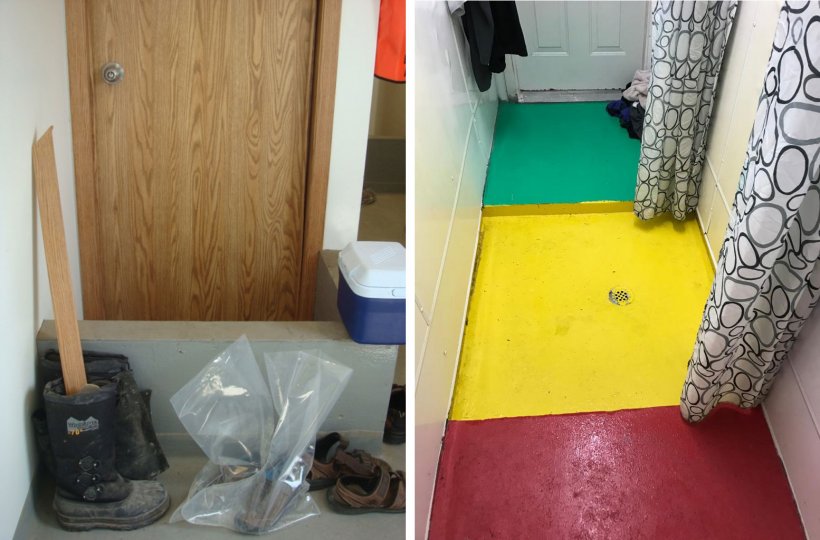

In this series of articles on low cost and high impact biosecurity, we will focus on how producers can implement the basic concepts of segregation on their farms to cost effectively prevent the entry of new pathogens. This article will focus on defining the ‘clean’ and ‘dirty’ zones and where producers apply the concept of segregation between these zones (Picture).

Remember that segregation involves the creation of barriers that are physical and/or temporal to control what and/or who goes through them. These barriers could be very well defined, such as the perimeter fencing and gates around a farm, or they could be more conceptual in nature, such as the ‘red line’ on the floor to remind workers the no-go areas.

When talking about segregation at farm level, most of our biosecurity conversations focus on defining the physical separation of zones to decrease the chance of disease transmission. We normally refer to these zones as ‘CLEAN’ and ‘DIRTY’. With ‘CLEAN’ being defined by the location of the animals that we are planning to protect. This zone contains only the pathogens that are a normal part of their ‘health status’. The ‘DIRTY’ areas are those that surround the ‘CLEAN’ areas and have the potential to be contaminated with pathogens that are not part of that farm’s ‘health status’. When a rise on contamination occurs, an inadequate segregation of the areas increases the chances of entry of diseases!

Defining the boundaries between ‘CLEAN’ and ‘DIRTY’ zones cannot occur without the consensus of veterinarians, producers and workers that protect the animal health. Ensuring that workers understand the concepts that guide biosecurity is critical for their implementation. Allowing workers to participate and contribute to the design of the biosecurity process helps ensuring the convenince and compliance with biosecurity directives. Without the worker acceptance, 24 hour a day/7 day a week biosecurity becomes impossible!

What needs to be moved onfarm and where are the critical clean/dirty zone boundaries?

- Vehicles movement → Gates, Fences

- Animal movement → Load Outs/Ins, Dead stock room

- Supply movement → Decontamination rooms, window with direct access to the office

- People movement → Farm entry, loading protocols

How can we design effective zone separation? What rules do we need to implement to make an appropriate transition across these zones? In the following articles we will focus on low cost, high impact methods commonly used in the swine industry to attain effective biosecurity.