Recently we looked at how to objectively control external biosecurity, through digital visitor logbooks for all types of farms, as well as systems for access control on farms with a high genetic level or in more complex company structures. So, we still need to provide an answer to the objective monitoring of internal biosecurity, which until now could only be done through surveys, farm visits, or periodic audits.

First of all, it is important to define that the objective of internal biosecurity is to prevent a disease that already exists on the farm from spreading to different areas.

The innovative digital biosecurity control system is mainly focused on the control of diseases with a major economic impact, such as PRRS. This system is made up of different bluetooth transmitters that are installed on the farm, allowing us to know which routes and management are carried out by the staff. Each worker receives a small portable transmitter with bluetooth technology, which must be used throughout the whole work day. At the same time, proximity detectors with the same technology are installed at all entrances to each building, including changing rooms and showers.

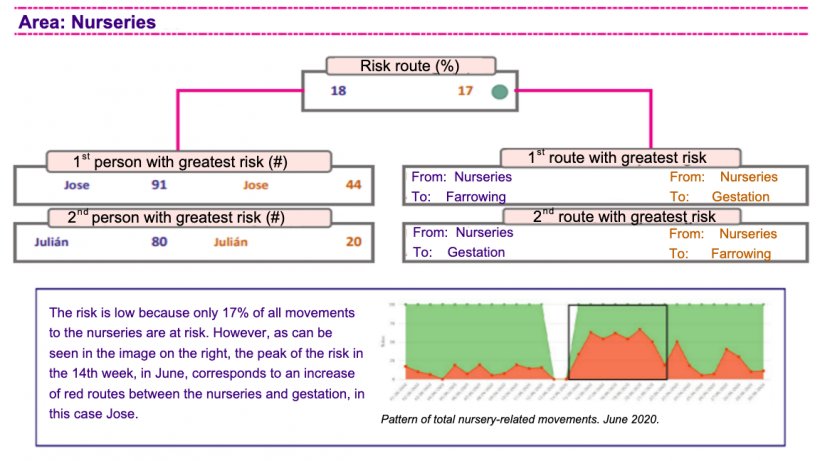

On each farm it is essential to determine the specific risky movements, theoretically defined as those that originate in an infected zone and are directed to an infection-free zone. These should be determined after a detailed study of each farm, as the system is flexible and dynamic, and can be modified at any time thereafter if the risk changes. Once the system is up and running, the receiving devices allow the movement patterns of personnel to be known in real time and, after detailed analysis by technical personnel, the risk of disease spread within the farm can be determined (Figure 1).

Figure 1. Analysis of the movement pattern on a farm with the digital biosecurity control system.

With this system, the relationship between risky movements and the presence of PRRS virus has been established (Diaz et al., 2020). For this purpose, animals from all farm buildings were tested by PCR and ELISA for PRRS virus and in this way, the buildings were classified into those that were positive for the virus, with at least one positive PCR, and negative buildings. Finally, the positive relationship between personnel risky movements and animal viremia was demonstrated, concluding that buildings that were classified as PCR positive had an average of 6.3% risky movements, while in negative buildings it was only 2.6%.

It has also been possible to control diseases such as PRRS (Arruda, 2020), and to demonstrate the relationship between biosecurity and production efficiency on farms in the USA (unpublished data). According to this author, on PRRS-positive farms, a 5-hour increase in the person in charge spending time in farrowing rooms was associated with an increase of one weaned piglet per 10 litters. On a second farm, an increase in farrowing room time of approximately 2 hours per worker per week increased the number of piglets weaned by 1 piglet per 4 litters. These results could be related to an increase in animal care, leading to a higher number of weaned animals.

Having all this information facilitates the monitoring of internal biosecurity and offers a dynamic system, making it possible to update and adapt it through the feedback generated.

It seems therefore that the combination of classical techniques (surveys and audits) together with the expert knowledge of the veterinarian and, together with the objective data obtained automatically, represent the best possible combination to ensure biosecurity control on any type of farm, since the cost of these systems makes it affordable for any producer.

Finally, it should be noted that at the present time, remote control is more convenient and even more necessary than ever, with it being possible to know in real time and from any mobile device if the protocols are being met and being able to act quickly to prevent or control damage.