Sow feeding during lactation is one of the factors that has the most influence on the whole production cycle of breeding sows and on the performance of the farm.

Feeding of sows in lactation affects, in part, milk production and therefore the viability and wean weight of the piglets; along with the fertility and prolificacy in the next cycle, and in a way, by affecting her body reserves it also affects the longevity of the sow.

A sow's milk production increases progressively, with production peaking around two weeks of lactation.

It is commonly accepted that feeding should follow an increasing feed intake curve after farrowing reaching the maximum point starting at the second week of lactation.

Today, in high producing sows, it is necessary to achieve maximum feed intakes of around 10 kg, with the average daily intake during lactation being about 6 kg.

How to properly perform this feeding has never been an easy task. Finding the point of equilibrium between pushing the maximum amount of feed without giving too much is not an easy task. Even more difficult has become in the current farms with a large number of sows and different workers taking care of sow feeding.

Hand-Feeding

Up until fifteen or twenty years ago, feeding was basically all done by hand. The farmer distributed the feed by hand. Observing the sow and checking in the feeder if the sow had finished the previous meal, he decided how much feed he gave to each sow.

Among other factors, this traditional way of feeding determined the design of farrowing rooms, considering that the sows should have their heads facing the walkway, with the feeder accessible to distribute feed with a scoop or other dispensing tool.

On small or traditional farms, feeding is still done in this way.

Dispensers

Little by little, automatic feed distribution using spirals or chains and the use of feed dispensers took over

.Feeding with dispensers has its advantages:

- Manual labor of feeding by hand is avoided.

-

It allows the worker to decide, at any time, the amount of feed every sow will receive.

- Makes the distribution of feed easier by different workers.

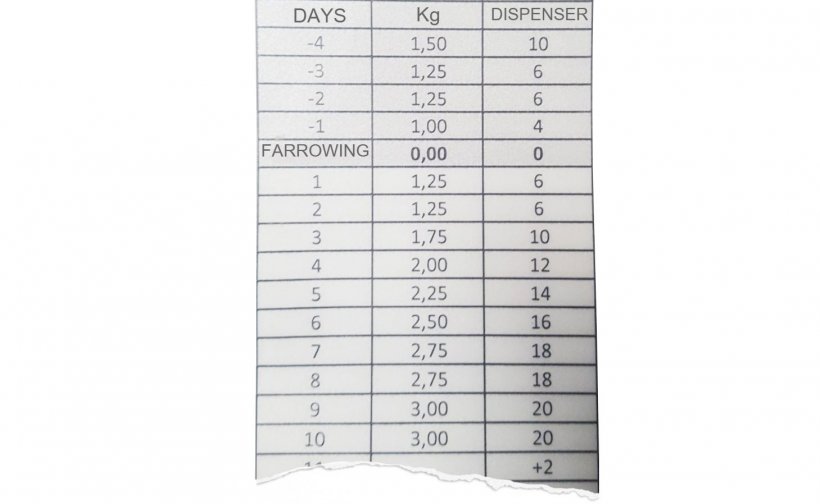

However, it is required to daily adjust the majority of the feed dispensers in order to increase the ration (Figure 1).

Figure 1: It is advised to note the feeding curve, and daily adjust the feed dispensers depending on whether the sow has eaten or not.

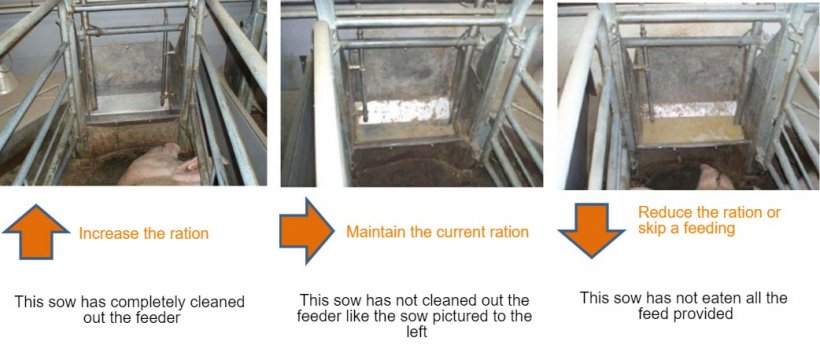

With the use of feeders, it still depends on the worker's judgement to decide if the sow should be eating more or not (Figure 2).

Figure 2: At least once a day sow feeders should be checked, and it should be decided if the sow can eat more or not depending on what is observed. Source: Pig Research Center

The Pig Research Center of Denmark came up with a golden rule: "In a farrowing room, the leftover feed should need to be cleaned out of approximately 8% of the sow's feeders; if this 8% is not reached, we are shorting the sows on feed, and many sows are not achieving their maximum intake. If we surpass 8% we are feeding too much feed and losing time and money."

With feed dispensers, as with any other system that measures out by volume, we should weigh the feed often, making sure that we are giving the weight expected, considering that the specific weight of feed varies, especially on meal feed.

Ad libitum feeding

As already stated, one of the great challenges of swine production has been, getting the lactating sow to eat as much as she can. To keep human error from limiting intake, systems have been and are being developed that look to free-feed the sows, without depending on the farmer increasing the feed or not.

This is why years ago systems were developed in which the sows ate from feeders similar to those that are used in finishing barns.

Even though many of these systems were filled manually or filled directly from the feed distribution system, these systems functioned better when they were combined with a dispenser (see photo 3).

Figure 3: With a feed dispenser, feed can be regulated more easily prior to and after farrowing, allowing free feeding later on.

The main problem with these hoppers was feed waste, as it is complicated to limit the amount of feed that the sows made fall, whether they ate it or not.

If the hopper included the water inside it, the feed waste increased even more. If the water was in a completely separate bowl, intake was limited as there is not an adequate water consumption.

Although the focus of this article is not water consumption, we cannot forget that any feeding system will fail if it does not go together with some watering system that allows for sufficient water consumption (a sow consumes up to 40 liters of water during lactation).

In the last years, feeding systems have been developed like the ad libitum system with feeding ball, or lately, electronic feeding systems which we will focus on in the next article.