The objectives are to reduce or minimize:

- Water consumption and flow rate of the slurry produced,

- Nutrient and heavy metal content of the slurry,

- Emissions of greenhouse gases, ammonia, and volatile organic compounds (VOC).

Water consumption

Reducing water consumption- with better monitoring of the drinkers, preventing losses or modifying the feeding; cleaning with high water pressure; or preventing rainwater from entering the slurry lagoon, reduces the volume of slurry and, therefore, reduces the storage volume and the cost of transporting the slurry to where it will be applied to the field.

Reducing nutrients and heavy metals

The flow of nutrients that end up in the slurry, especially nitrogen, can be reduced by using more digestible proteins and adapting the amounts and composition of the feed to the needs of the animals according to their age. Using phytases to make it possible for the animals to assimilate phosphorus allows the phosphorus lost to be reduced. Various feed modifications should allow better performance in the assimilation of nutrients and, therefore, lower losses to the slurry. After all, everything that is lost during feeding goes into the slurry, whether it is feed to be digested or the digested feed, which is the manure. Increasing the efficiency of the feed conversion to meat means reducing the mass of nutrients in the slurry, which translates into a reduced need for agricultural land for fertilization.

The presence of heavy metals in slurry, in particular, copper (Cu) and especially zinc (Zn), reduces the economic value of the by-products that can be obtained from slurry, whether they are concentrates or compost from the solid fraction. Reducing Cu and Zn in the diet can have a positive economic effect on the value of slurry and its by-products as fertilizers.

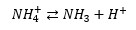

Nitrogen in slurry comes mainly from organic nitrogen from proteins and amino acids that have not been assimilated and from mineral nitrogen, mostly in the form of urea in the urine. This urea decomposes rapidly in the slurry during the first few hours and is converted to ammonium ion (NH4+). The ionized form of ammonium is not volatile, but it is in equilibrium in the liquid medium with the ammonia (NH3), which is a gas and will therefore escape into the atmosphere.

If the pH is high or the temperature rises, the equilibrium shifts to the right, forming NH3, which will tend to volatilize. In the opposite case, low pH (acidic) or low temperature, the equilibrium shifts to the left and the ammonium remains soluble in the slurry. This chemical equilibrium is important because it indicates that as the temperature inside the barns becomes comfortable, it is very likely that the nitrogen will be lost to the atmosphere in the form of ammonia, which the animals will breathe.

Gas emissions

Like ammonia, different organic compounds that result from the decomposition of slurry also volatilize (VOCs) and go into the atmosphere; some of them are also dependent on pH and temperature. It has been documented that removing slurry stored under the slats as soon as possible to avoid the decomposition to volatile forms of many compounds, results in improved air quality in the barns, reduced mortality, and increases in animal daily gain, feed conversion rates, and live weight sales. A reduction in antibiotic use has also been observed. This illustrates the need to quantify the positive impact that good slurry management can have on the farm production model, rather than just considering environmental management a cost.

When slurry is stored under the slatted floor, an anaerobic environment is created after a few days, which favors the growth of bacteria that produce methane (CH4), a gas that has a greenhouse effect 25 times greater than carbon dioxide (CO2). In this case, as in the case of ammonia and other volatile compounds, it is best to remove the slurry as soon as possible, every 24 hours, or even better every 12 hours if possible, to a covered outdoor lagoon. Covering the outdoor lagoon has an immediate effect in reducing emissions of ammonia and other odor-producing gases, but this only reduces methane emissions if the gas is used as energy or burned in a flare stack.

One of the gases emitted is hydrogen sulfide (H2S), a toxic gas with an unpleasant odor, which results from the transformation (in an anaerobic medium) of the sulfur contained in some amino acids and, above all, from amino acids that are provided in the form of sulfate (lysine sulfate, for example). The presence of these sulfates in the slurry also creates problems in biogas production systems. To reduce H2S emissions in the barns and to prevent problems in subsequent slurry processing systems, it is recommended to use amino acids in their anhydrous form.

To assess all the above actions, measuring is necessary to know the flow rates and concentrations and to schedule the monitoring of all the variables over time. It must be taken into account that the characteristics of the slurry are quite variable and depend on different factors: farm type or physiological state of the animals (finishing, breeding sows, nursery, farrow-to-finish, etc.), feed formulation, type of feeding (wet/dry), storage system, how old the slurry is (time elapsed since it was generated), time of the year (evaporation, frequency of slurry pond emptying, etc.) and water management (rainfall, type of cleaning, condition of the drinkers, etc.).

I have already implemented as many reduction measures as possible: