Biosecurity is increasingly becoming one of the main tools available to companies to improve farm health and prevent both internal and external contamination. However, one hindrance is that biosecurity is difficult to control due to the enormous number of factors involved. Consequently, staff training (managers, farm workers, maintenance workers, and truck drivers) has become a great ally to the people in charge of biosecurity, who every year, devotes more and more time and resources to train the employees.

But... how long does the positive effect of the training last? Does repeating the concepts every 6 months really ensure that refreshing courses have an effect retraining the staff?

One thing we can be sure of, is that constant monitoring, definition, and control of processes makes personnel more aware and careful of what they are doing. Nowadays, technology facilitates this monitoring in real-time, so that failures in biosecurity can be prevented or detected immediately.

The case presented in this article shows how the use of technology on biosecurity (in this case external) facilitates and improves protocol compliance.

A company with 45 sites (farms, a slaughterhouse, a feed mill, and a truck wash) starts using an external biosecurity evaluation system by means of digital control of visits and vehicles. The basic operation of the system is as follows:

- Data recording is done via the mobile app or GPS in the vehicles.

- The company defines its own biosecurity protocols according to the site type, health status, and type of visit/vehicle.

- Each time a visit is recorded, the system reads the company's biosecurity protocols and alerts whether or not the visit complies with the requirements.

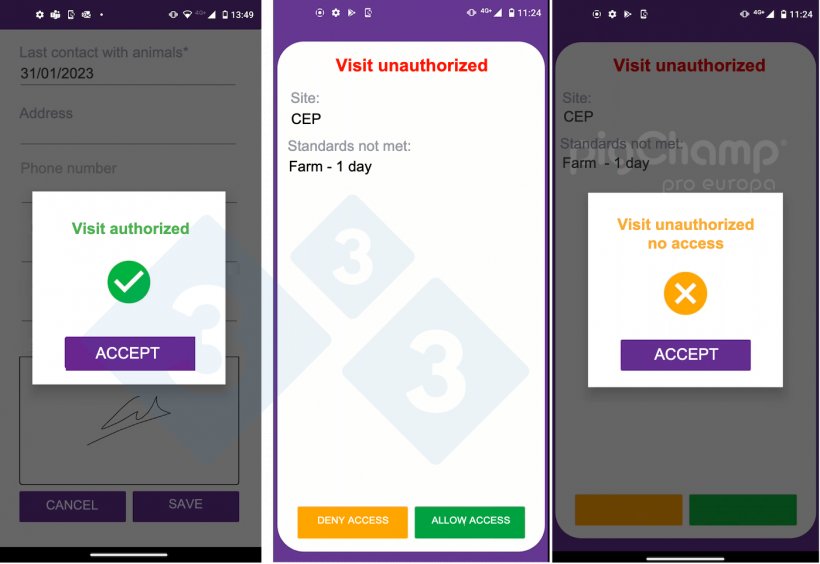

Movements are classified into 3 categories depending on whether the visit follows the company's rules or not:

- Authorized visit. There are no conflicts. It is allowed.

- Denied visit. Biosecurity protocols are not followed and the visit is denied, i.e., no farm entry.

- At-risk visit. Biosecurity protocols are not followed but entry to the farm is allowed.

The system is implemented and farmers are trained to record visits and authorize or deny visits that are automatically recorded by GPS (Image 1).

Photo 1. Examples of an accepted visit (left), unauthorized visit alert (center), and denied unauthorized visit (right).

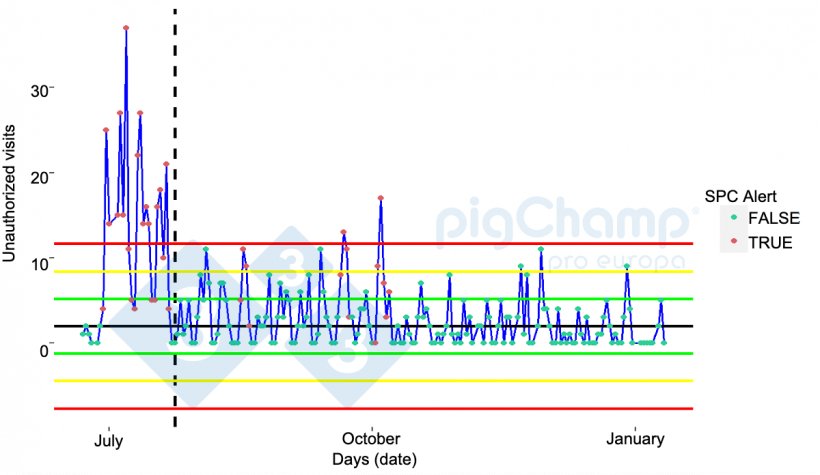

The data shown in Graph 1 are the records of denied visits and at-risk visits for the first 6 months of using the system. That is to say, the visits that, whether allowed or not, do not follow the biosecurity protocols defined by the company.

The data analysis performed (Mann-Whitney test, p<0.05) shows how, during the first 49 days of implementation, there are a high number of visits to farms that do not follow the rules. After this time, and thanks to accelerating learning, the number of unauthorized visits drastically decreases until a stable pattern is reached.

How did this drastic decrease occur? After a month of recording data and alerts, meetings were organized with all types of farm visitors (maintenance, visitors, veterinarians, transportation, etc.), to show them their own data and how it did not fit with the company's protocols.

From that time on, compliance with standards regarding the order of farm visits remains stable within the green (optimal) and yellow (acceptable) lines for most of the period analyzed. In the month of October, there is an upturn in the number of errors, once again going outside the red lines (not acceptable), which is quickly corrected.

Graph 1. Timeline analysis of the number of unauthorized visits.

Continuous monitoring of compliance with biosecurity standards through the use of technology provides companies with guarantees and helps personnel follow protocols.

We are continuing this work by adding health information to the system to analyze the existence of direct relationships between these data and possible movements of PRRS strains between farms. We will write another article soon with the results.