Before Spain joined the EU, the market for Spanish pork products was subject to the rules of state trade. That is to say, the autarkic will of the dictatorship did not allow free trade, and the state was the one who ensured that there were no shortages. In times of scarcity, the state authorized certain operators to import. In times of abundance and ruinous prices, the state intervened in the market by buying and storing carcasses to sell at a later date when the market had recovered.

Spain has been a full member of the EU since March 1, 1986. Being a member of the European common market meant total liberalization. Since ASF was present in the country, at the beginning Spain could not export pigs or pork. On the other hand, EU member countries could sell to Spain immediately after March 1986.

On May 15, 1989, Spain was declared free of ASF north of what was known as the red line. A few years later, total liberalization took place with the definitive confirmation of the eradication of ASF from the Spanish territory. We will never be able to thank the Spanish health authorities enough for this achievement, a real accomplishment.

During this long autarkic period, the market was oversupplied in the winters and systematically undersupplied in the summers. Especially with the advent of mass tourism.

In the winters, pig prices were at rock bottom and the less efficient farmers were forced to quit. This was the birth of the great Spanish integration: the farms that should have closed were rented by the most efficient farmers, who increased their capacities without having to invest. Large livestock business structures were created with hardly any capital tied up.

Some large feed manufacturers of the time began to integrate pigs.

At the end of the 1960s, a major change began in the industrial structures for slaughtering and cutting pigs. Many important butchers who slaughtered and cut as best they could (sometimes in the backyard of the store) were forced by the legal changes that followed to decide between ceasing operations or embarking on constructing modern slaughterhouses and cutting plants. Some of them decided to grow.

At that time, slaughterhouses were constantly immersed in an all-out struggle against each other. They learned - by force - to be efficient and very competitive. They learned to work obsessively saving costs to the maximum and optimizing each of the industrial processes they executed. They learned to be disciplined and professional.

It is worth mentioning that carcasses were cut warm in most cases. It was not until the 90s that cutting evolved to cold carcass cutting.

The day May 15, 1989 was a turning point for the future of the Spanish swine industry. For the first time in years, we could export. We arrived where the others were; quite late, admittedly, but we got there. Ignoring the most basic concepts of the international pork trade, but able to export.

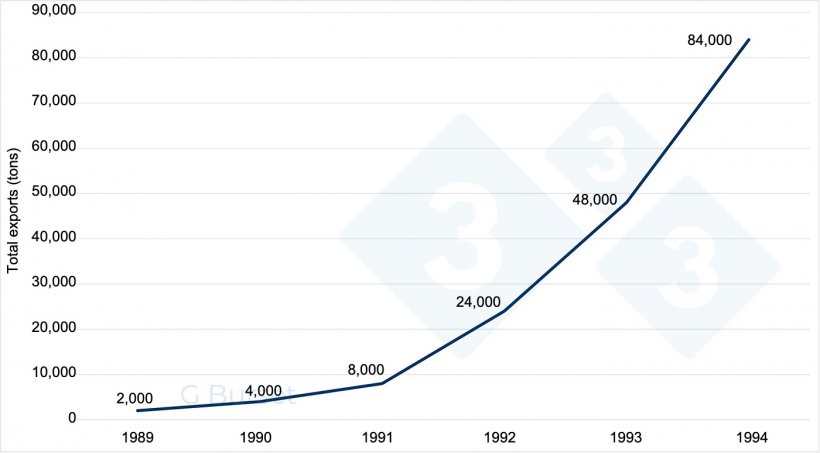

Let's review the figures for Spanish pork exports in those years (Graph 1):

Graph 1. Evolution of the start of Spanish pork exports.

These figures are derisory compared to today (we have been exporting more than 2 million tons for several years now...). Moreover, we exported without any tradition or know-how. Nowadays we export more than 50% of the pork produced in Spain.

To get the right perspective we shall mention that in 1989 the total pig slaughter in Spain was 29,000,000 animals. We will return to this figure later in this text.

|

To reinforce the reader's understanding, we will allow ourselves the license to share an anecdote from those years of collective learning: I was in Cologne (Germany), back in 1994, attending to a complaint from a German customer and, suddenly, the customer told me,  "When I receive Spanish pork in boxes, it's as if each one is a Christmas present." Clearly, the customer was waiting for my obvious question, “Oh really? Why is that?” His response paints a picture of how Spanish pork was back then, "Because I never know what I'm going to find inside each box." |

Let's put that conversation in context: at that time Denmark (and other countries close to its level) delivered their pork carefully packaged and the pieces inside each box were very neatly arranged. Today, Spanish operators have learned everything there is to know in this respect.

The fact is that exports allowed the winter surpluses to find a comfortable place (at a good price), bringing oxygen to the production accounts of farmers, slaughterhouses, and cutting plants.

We have always thought that the industry (slaughterhouse + cutting plant) is the real filter for pork's access to world markets.

The evolution of things and the character of people have led Spain to have an extremely efficient industrial swine industry (slaughterhouses and processing plants). For us, this efficiency is one of the cornerstones that explains the success of the industry as a whole.

Giant strides have also been made in pig farming. The large integrators realized that it was necessary for them to have their own dams and they acquired them. Management and health were made professional, they learned from the most advanced countries, and above all, they became disciplined in doing things well. The efficiency and professionalism of Spanish farmers is another cornerstone that explains the success of the Spanish industry as a whole.

We understand that the first years in which Spain was able to export were guesswork. Trial and error most of the time. The most outstanding operators realized that they needed to learn from the best. And that's what they did: they traveled to see the world and see successful experiences in other places. And to acquire industrial process know-how from those who had it.

In those "early years" the truth is that there were many hidden concomitant factors that converged in a spiral of success:

- Most of the restructuring in the pig farming industry was done: the less efficient had been forced out by the implacability of the market. And those who remained were willing to do whatever it took.

- The slaughterhouses and cutting plants were among the most efficient in the world, probably without being clearly aware of it. Access to the international market was a formidable injection of economic and professional optimism; a formidable lever for forward projection.

- The temperament and character of most of the managers of the companies in the industry were suitable for the time: adaptability, flexibility, persistence, will to succeed, obsessive capacity to save and optimize, resilience... All of these qualities are present in any successful company that survives to this day.

- EU membership guaranteed that we would play by the same rules as our EU partners. An egalitarian factor that we consider to be decisive. Legal regulations of all kinds bind all members equally.

Guillem Burset