Feed is the most important area in pig production and represents the highest cost within the production system, accounting for between 70 and 75% of the total cost. A clear example of this can be found in Latin America, where most countries, with the exception of Brazil and Argentina, are importers of corn and soybeans, the basic ingredients that generally account for 80% of a typical diet in the region. This situation makes the cost of diets higher, and makes feed intervention the most relevant strategy when seeking an effective reduction in production costs.

Nutritional strategy and the value of weight gain

Understanding the relationship between nutrition, performance, and profitability is essential and allows nutritionists to establish an effective nutritional strategy. During the growth and finishing stages, which account for most of a farm's feed costs, it is essential to precisely define the nutrient concentration of diets, mainly energy, amino acids, and phosphorus, based on the target response variable: feed conversion, weight gain, cost per kilogram produced, or gross margin on feed costs.

Since there is not always a direct and proportional relationship between performance variables (feed conversion and weight gain) and profitability, it is recommended that the nutritional strategy should be designed to maximize feed efficiency or to minimize productive losses, depending on the market context.

An effective nutritional strategy should be based on identifying the market timing, taking into account the production cost and the selling price of the meat. The greater the positive difference between the two, the higher the value of daily gain will be, and therefore, the strategy should focus on accelerating growth to reach the highest possible weight in the shortest time allowed by the facilities.

On the other hand, when the production cost exceeds the selling price, the value of daily gain will be negative, so it is advisable to implement strategies that slow the growth rate or even bring forward the sale at lower weights.

This aspect also depends on whether the production system is “fixed time” or “fixed weight.” In the former—more common in Latin America—space is the main limiting factor in getting pigs to higher weights, so good market conditions justify accelerating growth. In “fixed weight” systems, faster growth will only provide the additional benefit of sanitary downtime, which does not always represent a significant economic advantage.

Key elements for an effective nutritional strategy

1. Precision in ingredient parameters

Since nutritionists use formulation software at minimal cost, it is essential to minimize deviations between the actual composition of the ingredients and that used in the software. Tools such as wet chemistry, near-infrared spectroscopy (NIRS), and high-performance liquid chromatography (HPLC) allow for accurate analysis of ingredients. Underestimation can increase the cost of diets, while overestimation can affect animal performance. For example, there are significant variations in lysine content in corn and soybean meal samples from the same source.

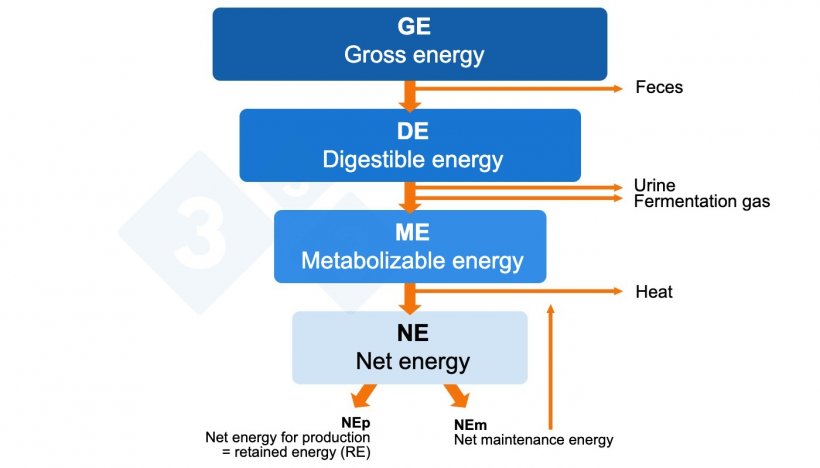

2. Formulation based on the net energy model

The net energy (NE) formulation model allows for a more accurate estimate of the pig's energy requirements, as it accounts for heat losses during digestion and metabolism. Ingredients high in fiber and protein generate more heat, so formulating based on NE improves accuracy and can reduce feed costs.

3. Nutrition management models in companies

In Latin America, as in other parts of the world, different nutrition management models coexist, depending on the type of market. Some producers buy complete feed (commercial formulas), others manufacture their own feed, and still others have to operate under a toll manufacturing model. In each case, there is an opportunity to optimize the cost of diets if effective intervention is made in the nutrition model.

One option for those who purchase finished or complete feed is to evaluate the feasibility of outsourcing (toll manufacturing model) or manufacturing their own feed, depending on volume, ease of access to ingredients at competitive prices, and the availability of adequate nutritional consulting.

For them, there are two nutrition models: closed and open.

- In the closed model, the producer purchases premix or basemix, which include low-inclusion ingredients (vitamins, minerals, enzymes, additives, medications, amino acids, etc.). This model is more practical and safer, but tends to make diets more expensive. It is ideal for producers who do not have good purchasing power for the aforementioned ingredients, or for those who do not have the conditions, equipment, or personnel for weighing and dosing small quantities.

- In the open model, the producer purchases a vitamin-mineral premix and manages the low-inclusion ingredients separately. It requires greater operational capacity, but allows for greater control and savings.

4. Availability of alternative ingredients

Corn and soybeans are the main ingredients in pig feed, but dependency on them is a risk. Exploring alternatives such as sorghum, cassava, distillers dried grains with solubles (DDGS), wheat by-products, rice flour, cookie flour, expired snacks, pasta, or avocado by-products can result in significant savings. Limitations to their inclusion may be related to their nutritional stability, seasonality, and energy and amino acid content.

5. Use of exogenous enzymes

Many ingredients contain unusable fractions, but the inclusion of exogenous enzymes (phytases, carbohydrases, proteases) can release key nutrients such as energy, phosphorus, and amino acids. When formulated with nutritional matrices, these enzymes can reduce costs without affecting performance.

6. Purchase management

The supply strategy is key to controlling feed costs. Some recommended actions are:

- Planned purchases taking advantage of low prices.

- Storage of long-lasting ingredients.

- Competitive bidding.

- Diversification of suppliers.

- Formation of cooperatives or purchasing groups to consolidate volumes and negotiate better prices.

In conclusion, reducing costs in pig feed formulation does not depend on a single action, but rather on the strategic integration of multiple factors: precision in formulation, ingredient selection, use of technologies such as enzymes and energy models, and efficient purchasing management. Adapting these tools to the production context and market conditions not only reduces feed costs, but also optimizes the profitability of the system.