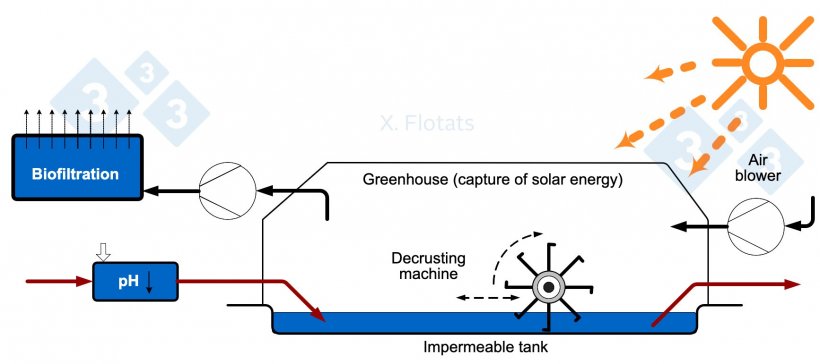

Solar drying consists of taking advantage of solar energy to evaporate part of the water in the slurry in order to reduce its volume and facilitate its export. Therefore, it may be useful to study this alternative in a situation where there is a nutrient surplus, either alone or in combination with one of the other three strategies (based on biogas production, based on physical-chemical separation and filtration, or based on nitrogen removal). Figure 1 shows a diagram of one of these installations and Figure 2 shows a picture of one of them.

This system seeks to reduce the volume of the slurry to facilitate its transport and export, which could also be applicable in a non-surplus situation. Therefore, partial evaporation (e.g. evaporation of 50% of the water) may be sufficient.

Figure 1. Diagram of an installation for solar drying of slurry or its solid fraction.

The thermal processes of concentration by evaporation and drying can also be carried out by taking advantage of the solar energy incident on a greenhouse through which slurry or solid fractions circulate, with the help of a mechanical rake system or a mobile machine that breaks the surface crusts, which reduce the transfer of humidity to the greenhouse atmosphere. The greenhouse air must be renewed in a controlled manner to avoid saturation of humidity.

The main limiting factor is the possible volatilization of NH3 or other compounds, so at least the pH in the slurry must be controlled, with the addition of acid, and the emissions produced, basically organic compounds and residual ammonia. Therefore, the humid air extracted from the greenhouse must pass through a biofilter or other treatment system to keep emissions under acceptable values.

The sizing of the installations should be based on the incident solar radiation throughout the year, the relative humidity of the atmosphere, and the flow of water to evaporate, so the design should be adapted to local conditions. In different tests carried out with experimental greenhouses in the conditions of the Aragon and Catalonia regions in Spain, in the winter the water evaporated can be below 1 kg/m2-day, while in summer it can be between 4 and 9 kg/m2-day, depending on the location (Prenafeta-Boldú and Parera, 2020). These values can provide an initial approximation to estimate the area needed for the greenhouse.

Figure 2. Picture of a solar drying system using a greenhouse. In the foreground is the acid tank and a biofilter for the treatment of gaseous emissions. (Courtesy of J. Soler, EMA depuració, Olot, Gerona)

Return to the nutrient surplus situation to study other technological strategies