Facilities are a key part of our production. Together with health and management, these are the three pillars we rely on for our animals to reach their maximum potential and to be efficient.

The cost and investment we make in sow farm facilities is one of the most significant economic items that affects us when assessing the farm's economy. Although it can vary significantly, we can estimate the cost for farm maintenance to be between 0.7 and 2 euros per piglet produced, a remarkable figure that depends on many factors, such as:

- Condition of the facility (how old it is and the quality of the construction and equipment).

- Level of standards that we set for the maintenance of the facility.

- Good design and, consequently, good use of the farm.

The elements or materials that represent the most frequent incidences on sow farms tend to be:

- Water pumps

- Chain feeding systems or feed augers

- Pressure washing pumps

- Window or air inlet motors

- Fans

- Air conditioning control units

- Electrical and/or electronic equipment (differentials, circuit breakers, surge protectors, electronic boards, etc.)

- Electronic feeding stations

- Animal housing equipment (feeders, dividers, drinkers, gates, etc.)

Types of maintenance

Maintenance work on a farm can be divided into three main types:

Corrective maintenance: anything that has to do with breakdowns or failures in the operation of any equipment or mechanism.

Preventive maintenance: periodic and schedlued actions to prevent future breakdowns and to extend the working life of some mechanisms.

Photo 1. Electrical panel sanitation in a pumping room.

Predictive maintenance: based on observations and continuous monitoring, its objective is to detect any condition or wear that may cause a breakdown, before it occurs, so that replacement or repair can be arranged before it becomes a problem on the farm.

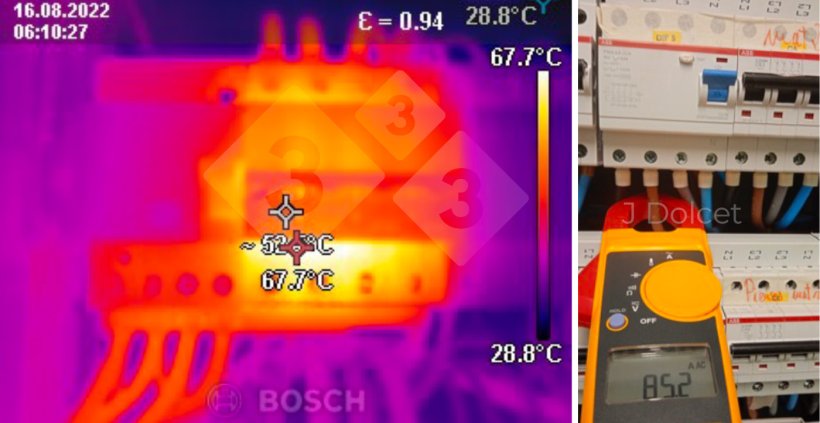

Photo 2. Detection of a possible fault with thermography (left) and with the well-known tester (right).

Artificial intelligence is included in this type of maintenance. Projects such FarmTwin are intensely being developed to create digital twins, which will be important in the near future.

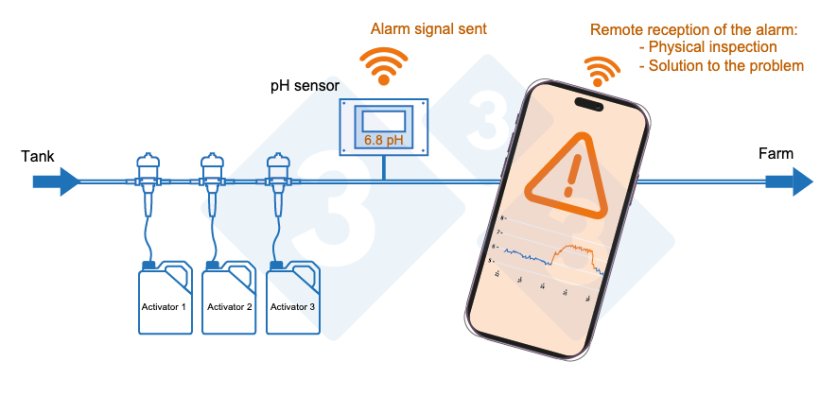

Photo 3. Remote monitoring system for the water shed.

A farm's reality is the coexistence of these three types of maintenance. Even so, it is logical to think that good planning and investment in PREDICTING or PREVENTING will allow us to CORRECT less often, reduce the risk of committing biosecurity errors due to haste, prevent us from wasting time on tasks that are not important, and be able to dedicate time to tasks such as the daily management of the animals.

Tools to enhance preventive maintenance

It is essential to have a digital support tool in which each operator records his activities. In this way, we can know how long, for example, a pressure washer has been installed, when that expensive boiler part was last replaced, or how many electronic boards have been replaced so far this year on a particular farm. We can also check the work carried out by the operators and their efficiency.

Along with this tool for recording incidents and events, it is essential to schedule some actions, such as:

- Engine oil and/or filter changes

- Lubrication of elements

- Review of anomalous electrical consumption of any motor

- Change of parts according to working hours stipulated by the manufacturer

How do we manage the health risks that maintenance poses to farms?

One of the areas that most compromises sow farm maintenance is undoubtedly biosecurity, especially when outsourcing maintenance services. In this case, it is essential to have disinfection and control points for all the materials that have to enter the facility. In addition, we need to have a high degree of trust with the contracted companies to avoid unauthorized visits, i.e., from other farms without respecting downtime without animal contact. In addition, it is essential to follow the protocol for entering a farm, which is based on showering, wearing the farm's exclusive clothing, and not bringing in phones or unnecessary materials. It is important that farm managers ensure compliance with the protocol.

The safest option, and at the same time the most difficult one to manage, is to train and have our own maintenance personnel. This professional profile is difficult to find, due to its versatility, training, specificity, and a higher salary range than some of the more common roles on farms. Size is another limiting factor. On large farms, a person could dedicate a large part of his or her time to controlling the maintenance of the farm. On the other hand, on smaller farms, he/she could combine it with some support work in animal management. In companies that manage different farms, it is common to have work teams that have to move between farms, following basic biosecurity criteria.

Photo 4. Inventory control of materials controlled in a warehouse external to the farms.

In summary, managing a facility's maintenance depends on several factors. The following is a summary of the most important ones:

- Prevention

- Task schedule

- Documentation and reference of the work performed

- Correct choice of materials and mechanism design

- Control of spare parts stock, to speed up work and avoid biosecurity failures

- Opting for new technologies that can help us in predictive maintenance. Here we find tools related to artificial intelligence, which will undoubtedly give our industry a lot to talk about.

As is often said among technicians who visit farms, the best visit is the one you don't have to make.