Where do we stand in regards to disease control and technology?

We all know that infectious diseases are one of the main nightmares of swine farmers. Diseases such as PRRS, PED and Mycoplasma affect our herds in a daily basis, and producers have to make decisions in collaboration with their vets on what to implement on their farms to best control and / or eliminate pathogens from their herds. Transmission of pathogens via fomites (inanimate objects that can carry them around) plays an important role on the maintenance and spread of pathogens in a herd, thus strong biosecurity protocols need to be implemented on farms for proper disease control.

There is normally a set of internal biosecurity measures recommended for implementation for cases in which the producer wants to control and eliminate diseases inside an infected farm. These normally include limiting cross-fostering between farrowing rooms, designating people to specific parts of the farm, change of boots and coveralls between different areas of the farm, etc. However, investigation on whether certain types of movements are associated with production parameters of interest (e.g. number of piglets weaned per sow and pre-weaning mortality) has not been reported.

Over the past years, we have seen an increase in the use of technology in pig farms. Technology has been out there for some time for features such as ventilation systems and monitoring of air quality and temperature, but we are living an era in which technology is also being investigated and applied for animal health. One example is the use of automatic feeders and, more precisely, individual-level, real-time data that such systems may be able to provide. However, the use of technology for evaluation of biosecurity compliance has not been previously investigated.

What did we investigate with our study?

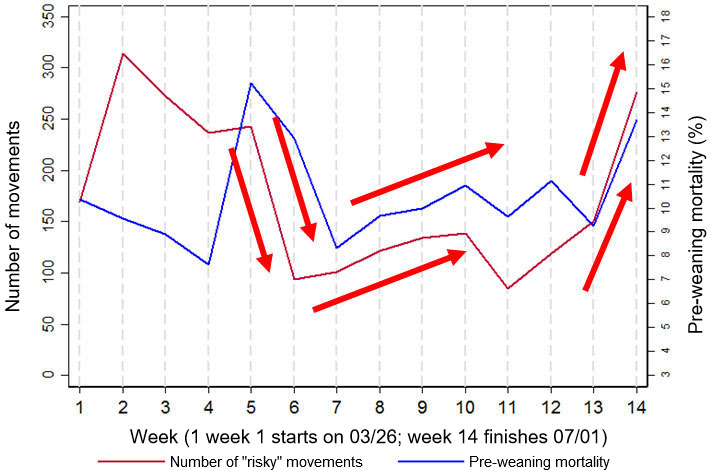

The objective of our study was to use technology to identify specific types of movements associated with production parameters, including number of pigs weaned per sow and pre-weaning mortality. Furthermore, we wanted to quantify the changes in production parameters as “risky” movements (defined as movements to/ from loading docks and/ or nursery areas) increased in swine farms (so far, this last objective was only partially completed). Our ultimate goal was to better understand what these “risky” movements were to focus farmer’s efforts to minimize them.

What did we do?

We enrolled farms with different demographics and biosecurity protocols, but all had something in common: historical problems with PRRS; and the desire to either control or eliminate this pathogen. All farms were followed up for the period of one year.

Farm 1 was a 1,500-sow farrow-to-finish operation with no shower and no filter system; farm 2 was a 4,500-sow farrow-to-wean operation, with a single room as staging nursery, with showers and no filters and farm 3 was a 4,400-sow farrow-to-wean air-filtered shower-in operation with limited nursery space. For all farms, an internal biosecurity system was installed, internet services were optimized throughout the farms and sensors were placed in each room (Fig. 1). Sensors were set up to detect Bluetooth-based beacon devices, which were individually distributed to farm employees (Fig. 1). Movement data was collected for one year. A movement was defined when an employee spent at least two minutes in one room after traveling from another room in the farm.

What did we find out?

- For farm 1 (smaller farrow-to-finish farm with no shower and no filter system):

- Increase in number of movements from finisher barns to farrowing ➔ increase in pre-weaning mortality by 6.2% the following week ➔ recommendation: dedicated people to finishers

- Increase in movements between farrowing rooms ➔ decrease in pigs weaned per sow by 1.5 pigs/sow ➔ recommendation: improve biosecurity between farrowing rooms

- For farm 2 (larger farrow-to-wean farm with showers but no filters):

- Increase in movements from nursery to farrowing ➔ decrease in pigs weaned per sow by 4.9 pigs/sow two weeks later ➔ recommendation: reduce this movement type

- For farm 3 (larger farrow-to-wean farm with showers and filters):

- Increase in movements involving supply rooms ➔ decrease in pre-weaning mortality and increase in pigs weaned per sow ➔ these results were less intuitive; but we hypothesize it may be the case that the improvement seen on production parameters are related to pig care, as both movements involve supply rooms.

Finally, using a subset of data (preliminary analysis), we showed that an increase in pre-weaning mortality by approximately 3% was observed with an increase of “risky” movements the week prior; and an increase in “risky” movements tended to result in a decrease in the number of piglets per litter by 0.37 (Fig. 2)