Faced with the need to reduce greenhouse gas emissions, the European Union and France have set the goal of carbon neutrality by 2050. Among the proposed actions to be taken is managing livestock manure.

In collaboration with Idele (Institut de l'Élevage) and Itavi (L'institut technique des filières avicole, cunicole et piscicole), IFIP (Institut du porc) has developed a calculator (in French) to find the cost per ton of CO2 saved by changing manure management practices on pig, cattle, and poultry farms. The calculator compares standard manure management with alternatives.

In the swine industry, standard slurry management consists of storing it in pits under the barns and then transferring it to open-air lagoons while the alternative practice is to remove the slurry daily via mechanical scraping of the pits and subsequent anaerobic digestion.

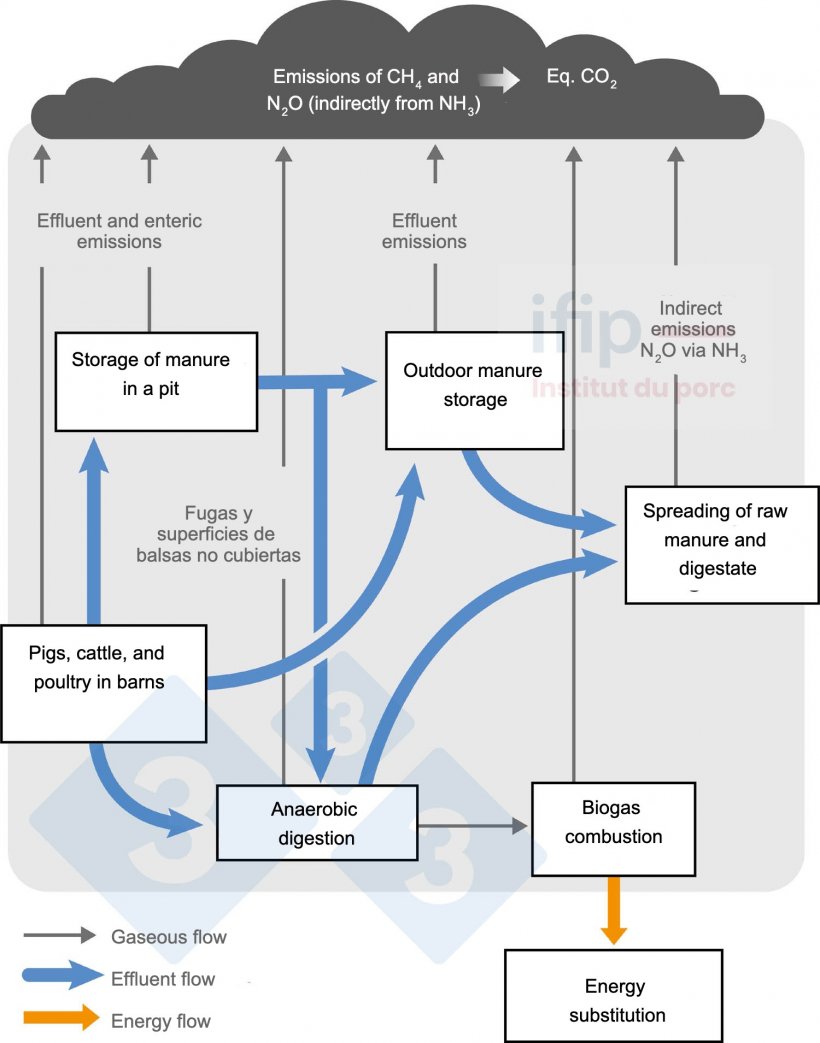

Diagram of the calculation parameters of the calculator (in gray). Source: IFIP.

The diagram shows the scope of gaseous emissions taken into account by the calculator developed by IFIP. The technical data (methanogenic potential of anaerobically digested effluents, combustion of collected biogas, biogas leakage, etc.) and economic data (investment and operating costs of changing practices) are given by the tool, but can be modified by the user.

Reductions

The daily removal of finishing pig slurry by mechanized scraping and the installation of a biogas collection cover on the outdoor storage lagoon (psychrophilic anaerobic digestion) of a 300-sow farrow-to-finish farm allows for a 59% reduction in direct greenhouse gas emissions compared to standard management, i.e. 671 t less CO2 eq/year (472 vs. 1,143 t CO2 eq/year emitted under the alternative or conventional conditions, respectively).

These values are obtained considering a 90% covered storage lagoon, a 5% leakage of the collected biogas, the expression of 29% of the methanogenic potential of the slurry and the combustion of the collected biogas.

Frequent removal of pig slurry and its anaerobic digestion reduce the farm's direct greenhouse gas emissions by more than 50%.

In this example, under the conditions found in France, with an additional investment cost of €60/place for mechanical scraping, an investment of €113,000, and an operating cost of €3,000/year for psychrophilic anaerobic digestion, the cost per ton CO2e saved is €41. With an investment subsidy of 40% and heating savings of €10,000/year through energy substitution, this remaining cost is halved to €20/t CO2e. In this case, the cost calculations have not taken into account the possibility of mesophilic anaerobic digestion and the cogeneration and sale of electricity, although the calculator allows all these scenarios to be calculated. The calculator makes it possible to prioritize the technical and economic criteria that most influence these emissions and to identify priority actions.