Anaerobic digestion removes volatile organic compounds and mineralizes, which improves the fertilizer quality of the digestate and favors subsequent nutrient recovery processes, in addition to producing renewable energy (biogas) and helping reduce greenhouse gas emissions.

In surplus situations, when it is necessary to export nutrients, the first option is to export part of the digestate. This can involve a high transport cost which, if not affordable, makes it necessary to evaluate other alternatives in order of increasing complexity. Usually, the higher the technological complexity, the higher the cost of investment and operation, which will only be acceptable if it allows quality products to be obtained that have market demand and significantly reduce the environmental impact, so as to allow the livestock farming activity to survive. As complexity increases, so does the requirement for specialized operation, which is why it is recommended that the plant be collective, serving many farms, in order to take advantage of economies of scale.

The strategies summarized below in the simplified diagrams can be expanded with other process units, or further simplified by not employing one of the processes, e.g. composting or pelletizing.

In the case of collective plants, the transport of raw slurry represents an important cost, which can be minimized by transporting only the solid fraction, separated at the farm for the farms farthest from the plant. Understandably, a high nutrient separation efficiency is needed for these local separation systems in order to minimize the amount that will remain in the liquid fraction to be managed at the farm of origin.

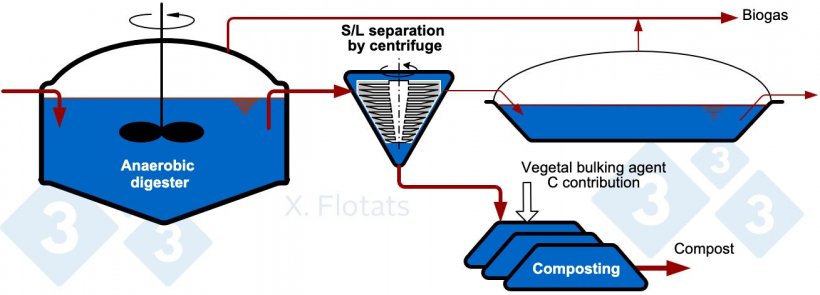

Anaerobic digestion combined with composting of the solid fraction

Figure 1. Diagram of the combination of anaerobic digestion and export of the solid fraction, with or without composting.

High-efficiency separation is necessary so that a significant part of the nutrients, especially nitrogen, can be exported as compost from the solid fraction. A carbon source must be available for composting. Alternatively, the solid fraction can be exported without composting. The ammoniacal nitrogen in the liquid fraction can volatilize, so it is necessary to cover the effluent lagoon and, if possible, recover the methane that will continue to be produced in the lagoon during storage.

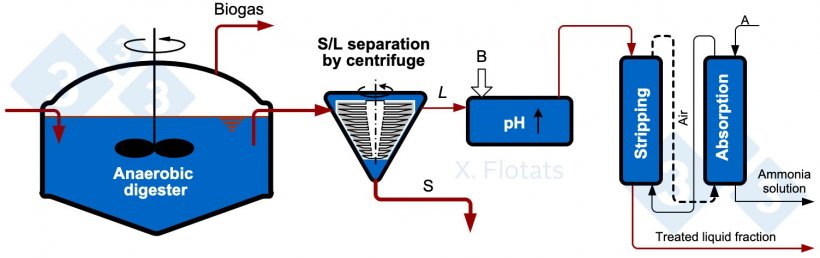

Anaerobic digestion combined with stripping and ammonium absorption

Figure 2. Diagram of the combination of anaerobic digestion and ammonia stripping, with export of the ammonia solution and the solid fraction, with or without composting.

The objective of the process is the desorption and stripping of ammonia in a column by means of an air or steam countercurrent (stripping column) and its subsequent recovery in a column with an absorbent acid (A) stream (absorption column). In liquid media, the ammonium ion is in equilibrium with ammonia, which is the gas that is stripped in the process. This equilibrium shifts towards ammonia with an increase in temperature and/or pH (by adding a base B, such as sodium or potassium hydroxide). One objective of the process is to obtain a quality product that has value in the mineral fertilizer industry, or for other uses. The previously separated solid fraction can also be exported, as is or after composting.

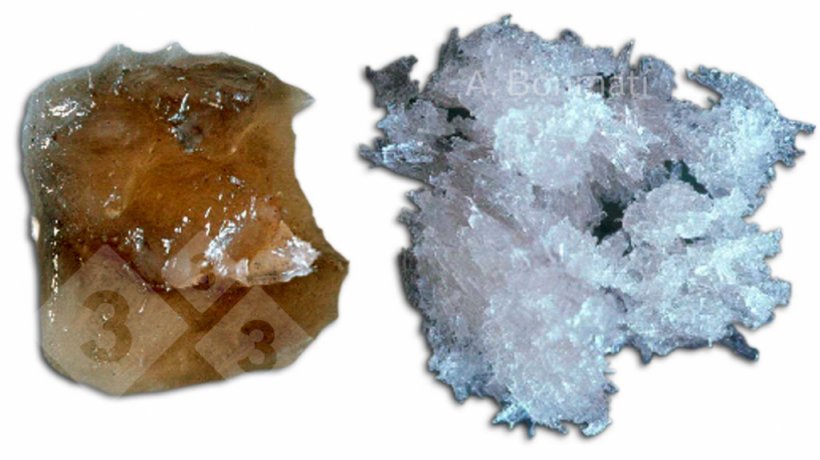

Contamination from organic matter, which is volatilized and carried away together with the ammonia, is the main limiting factor. For this reason, prior anaerobic digestion is advisable, whereby the organic matter is transformed into biogas, thus avoiding contamination of the product. Figure 3 shows that prior anaerobic digestion helps to obtain a higher quality product.

Figure 3. Ammonium sulfate crystals obtained by stripping and adsorption of: A) fresh pig slurry; B) anaerobically digested pig slurry. Photos courtesy of A. Bonmatí (IRTA).

The treated liquid contains a lower concentration of nitrogen (which will mostly be in the ammoniacal solution to be exported) and phosphorus (which will mostly be in the solid fraction to be exported), so the application rates for the fields must be calculated according to the limiting component, which will most likely be potassium or salinity.

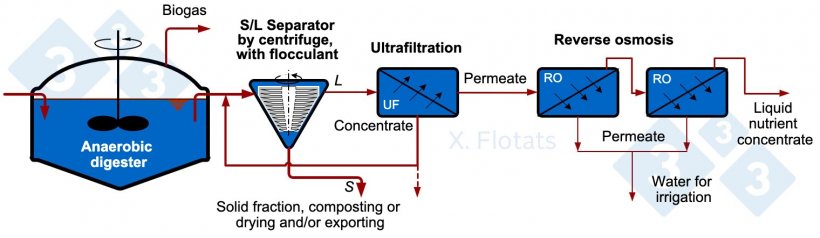

Anaerobic digestion combined with membrane separation of the liquid fraction to export the concentrate and the solid fraction

Figure 4. Diagram of the combination of anaerobic digestion and membrane processes (ultrafiltration and reverse osmosis) to obtain a nutrient concentrate to be exported as liquid fertilizer.

In this combination, the objective is to obtain a liquid concentrate of nutrients with no suspended particles or a minimum concentration of suspended particles, in order to give the concentrate value as a liquid fertilizer.

Membrane filtration processes consist of the separation of particles from a liquid effluent based on size or salinity by means of semi-permeable membranes. Of the different types of membrane processes, only reverse osmosis can concentrate salts; the others (microfiltration, ultrafiltration, nanofiltration) can only separate particles or molecules of high molecular weight. Reverse osmosis consists of reversing the osmotic flow of water (which would go from a dilute medium to a more concentrated medium) through a semi-permeable membrane by applying pressure, obtaining a permeate (dilute phase) and a concentrate. To avoid contamination, S/L separation and filtration systems must be applied prior to the process; therefore, an ultrafiltration unit has been added in Figure 4. Reverse osmosis can concentrate more than 99% of the salts, but small non-ionized molecules such as ammonia can pass through the membrane, so that the water obtained as permeate is not completely clean.

If a higher degree of concentration is desired than what reverse osmosis can offer, it is also necessary to combine it with vacuum evaporation, with condensate recovery for irrigation water. A concentrated solid fraction suitable for export is also obtained from the system, either with or without composting, or with or without drying. To minimize the suspended matter that is fed to the membranes, the use of a flocculant (polyelectrolyte) that improves the efficiency of the S/L separation by centrifugation is recommended.

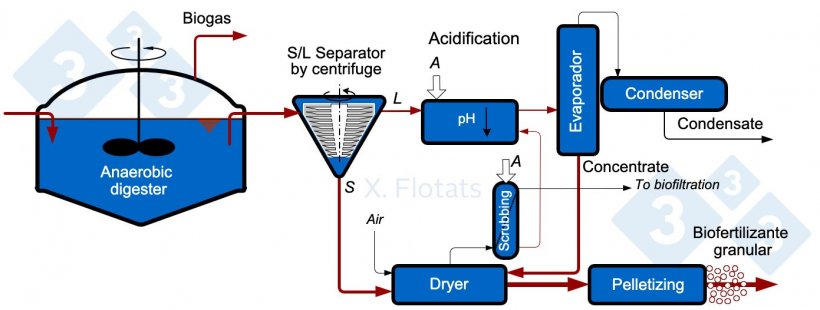

Anaerobic digestion combined with thermal concentration by means of vacuum evaporation and drying

Figure 5. Diagram of an installation for the production of granular biofertilizer from anaerobically digested pig slurry.

The objective of thermal concentration is the separation of the water content by evaporation, to obtain a concentrated product that maintains the initial nutrient load for subsequent transport and is given value. The thermal processes applied to concentrate are, generically, evaporation (applicable to liquids, to concentrate up to 20 - 30% in total solids) and drying (applicable to solids, to concentrate up to more than 90% in total solids). Thermal processes must be complemented with other processes to avoid deterioration of the material and loss by volatilization of organic compounds and ammonia.

To prevent vapors from causing atmospheric pollution problems, evaporation must be carried out under a vacuum and at moderate temperatures (50-70 °C), with recovery of the condensed water to be reused for irrigation or other uses. To minimize the concentration of ammoniacal nitrogen in the condensate, an acid should be added beforehand to lower the pH. The air and water vapor from drying should be treated with an acid scrubber, with recirculation of the liquid effluent to the pH reduction unit and treatment of the resulting air in biofilters. To minimize the content of organic compounds in the condensate, it is necessary to eliminate the organic matter beforehand, an objective that is achieved with previous anaerobic digestion.

It has been found that without prior anaerobic digestion, the COD (chemical oxygen demand) of condensate can be as high as 10,000 mg COD/L, whereas it drops below 130 mg COD/L with digestion. Also, acid consumption to lower pH prior to vacuum evaporation is also lower when anaerobic digestion is used.

The biogas that slurry can produce is not sufficient to cover the thermal energy demand of installations like the one in Figure 5, so co-digestion with food industry waste must be used to increase biogas production and reduce the water needed to evaporate, as well as other renewable energy sources.

I want to know more about anaerobic digestion

I want to know more about S/L separation systems

Could I replace the drying unit with a solar-powered dryer?

Return to the nutrient surplus situation to study other technological strategies