In a previous Pig333 article (“Debunking myths about biosecurity on swine farms”) we described how standardized outbreak investigations, conducted as an integrated biosecurity hazard analysis and epidemiological investigation, can be used to identify and prioritize biosecurity hazards for swine herds. In that article, a biosecurity hazard was defined as a circumstance, action or inaction that increases the likelihood of one or more of three failures. The three failures are:

- Failure to prevent contamination or infection of a pathogen-carrying agent (pigs, people, vehicles, etc.)

- Failure to mitigate the contamination or infection; and

- Failure to prevent transmission of the pathogen from the pathogen-carrying agent to pigs in the herd after the pathogen-carrying agent arrives at the farm.

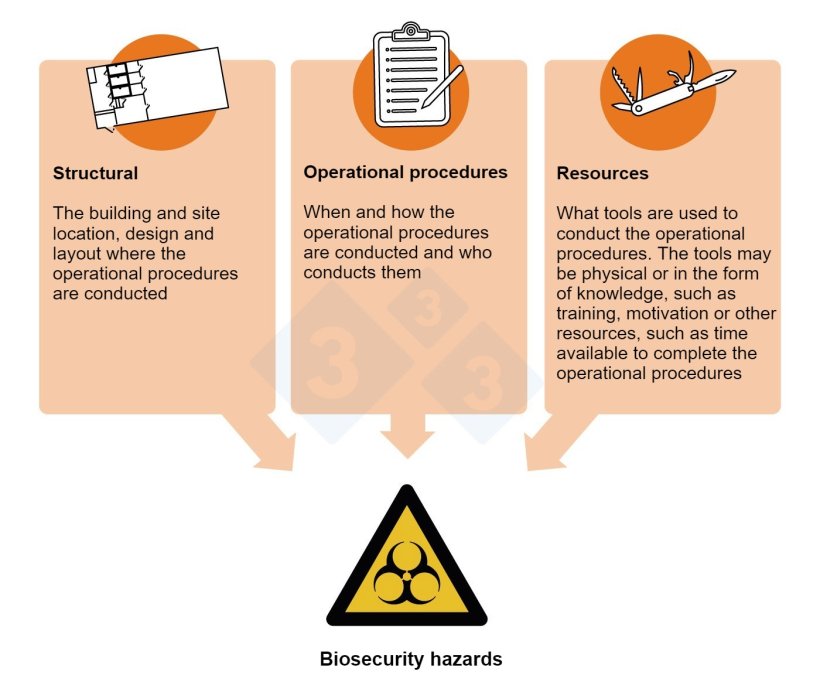

The biosecurity hazards arise from the execution of operating procedures including those required to raise pigs and those done strictly to reduce biosecurity hazards, such as showering in and out of the farm. Identifying the biosecurity hazards requires a deep dive into the production processes:

- Who does the operational procedures?

- What are the structural circumstances, facilities, and equipment with which they are done?

- When are they done?

- Where are they done?

- How are the operational procedures done?

The outcome of the investigation is a list of the highest priority biosecurity hazards that can be addressed with biosecurity control measures. A case study of how outbreak investigations are used to identify and prioritize biosecurity hazards and implement biosecurity control measures to address the hazards is described in this article.

Description of the outbreak investigation

A 5,000 sow breed-to-wean farm located in a relatively pig-dense area but with no known positive farms within a 16-km radius experienced a PRRS outbreak. An outbreak investigation using the Standardize Outbreak Investigation Program was conducted two weeks after clinical signs were first observed.

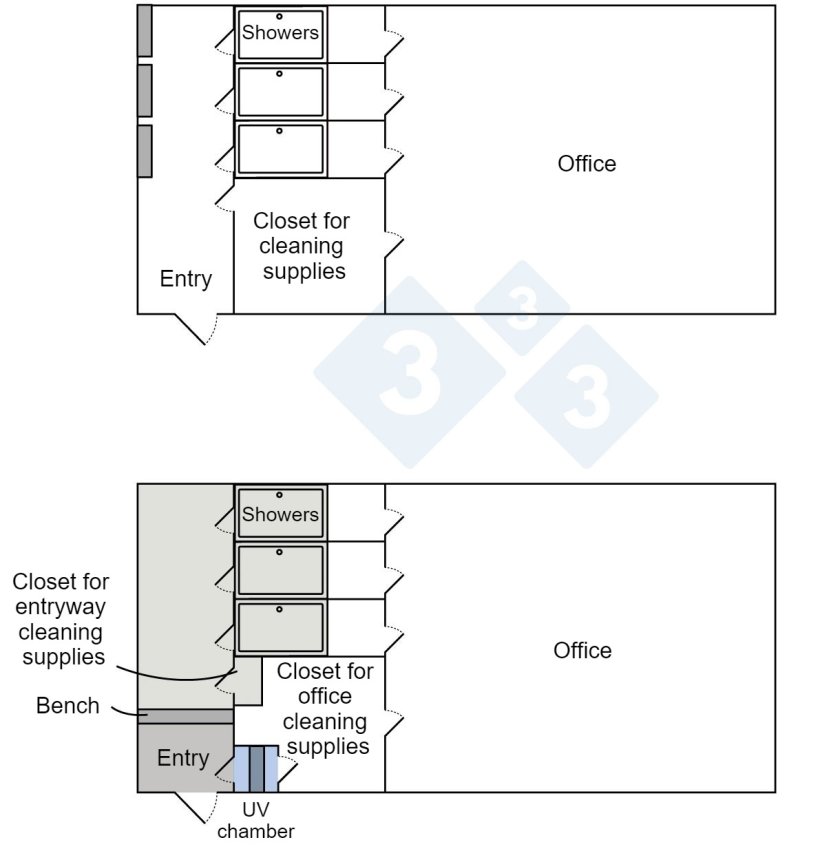

While the exact cause of the outbreak was not identified, the investigation revealed several significant biosecurity hazards associated with employee and personnel entry. The farm utilized shower in/out procedures for people entry and the showers were designated as the line of separation between the entryway and office. The farm lacked a bench entry, and we observed a significant amount of sandy soil on the floor of the entryway when we entered the farm, however, it was learned that the farm staff cleaned the entryway daily. The supplies to clean the farm were kept in a storage closet that was accessible from both the office (“clean” side of the line of separation) and the entryway (“dirty” side of the line of separation). The same cleaning supplies were used to clean the office and entryway including the mop and bucket. At the end of the workday, a single employee entered the storage closet through the door from the office, collected the cleaning supplies and proceeded to the entryway through the second door. The reverse of the process occurred when they finished cleaning the entryway after which they showered out.

Biosecurity control measures applied to address the biosecurity hazards

The biosecurity hazards were identified in various aspects of the production processes. The aspects of the production process where the hazards were found included the structural aspects, the procedural aspects and the resource aspects.

Aspects of production processes where biosecurity control measures can be implemented to reduce the biosecurity hazards are labeled critical control points. The critical control points may address the structural aspects of the production processes, the procedural aspects or the resource aspects.

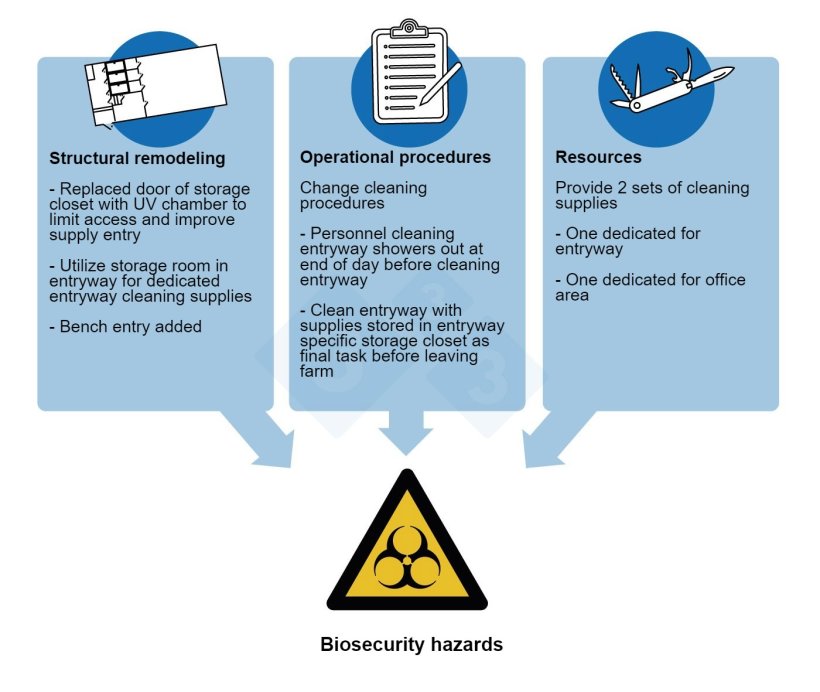

In this case, the showers were the intended line of separation between the entryway and the offices. However, the doors connecting the storage closet to the office and entryway created confusion about where the line of separation was located. This structural aspect was addressed by adding a bench entry to the farm. The door that accessed the closet from the entryway to the office was removed and replaced with a UV chamber. This change eliminated the ability to access the clean side of the office from the entryway unless personnel showered through the designated line of separation. The UV chamber also increased the biosecurity of personal and small supply entry into the office. A set of cleaning supplies dedicated for cleaning the entryway were moved and stored in a separate closet that was only accessible via the entryway.

The operational procedures were improved by adjusting the timing of when the entry was cleaned. The task was moved to the last task of the day after the employee designated to clean the entryway had showered out.

The resources aspect of the production processes were addressed by training all of the employees on the role and importance of the line of separation for preventing the introduction of pathogens into the herd. Employees were trained to always shower out and back in if re-entering the farm for any reason. Additionally, the proper tools were given to the farm staff to complete the entryway cleaning task by providing one set of cleaning supplies designated for cleaning the entryway and a second set of cleaning supplies designated for cleaning the office.

To be effective, biosecurity control measures must address the significant biosecurity hazards that increase the likelihood of transmitting a pathogen to a herd. The outcome of this outbreak investigation was to identify and prioritize several biosecurity hazards associated with the entry of employees and other personnel which resulted in biosecurity control measures being implemented to address these biosecurity hazards first. Other biosecurity hazards were identified, however, because the standardized outbreak investigation is systematic and comprehensive, we felt confident we had enough information to prioritize the biosecurity hazards that needed to be addressed first.