Introduction

Actinobacillus pleuropneumoniae (App) is the etiologic agent of swine pleuropneumonia, a highly infectious, often fatal disease. The main route of spread is by direct contact from pig to pig or by aerosol within short distances. Although some authors (Desrosiers, 2004; Kristensen, 2004) reported that airborne transmission between closely located pig units is possible but rare. The objective of this study was to follow up the spreading of App serotype 2 infection within a small pig herd. It is worth underlining that in Poland serotype 2 is one of the most predominant besides serotypes 6 and 9.

Farm description

A high-health multiplying farrow to finish herd (240 sows) was infected with App serotype 2 in August 2009. The herd was free of the major diseases including PRRS, EP, App and others. The farm consisted of two buildings 40 m from each other with no direct connection established between them. Shower facility and possibility of changing clothes and boots were available but only for the people working with animals, inside the farm.One building is devoted to grow-finish pigs managed AIAO by room and the other one is populated with sows and weaning pigs up to 7 weeks of age.

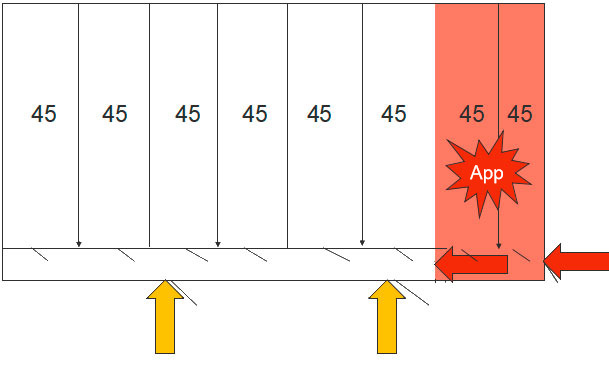

The grow-finish building consisted of 4 rooms split, each containing 2 pens with 45 pigs in each.

Case description

The infection entered into the grow-finish building in one of the outer rooms which was separated physically from the other part with a solid wall. Once the first symptoms of the infection emerged in pigs (temperature 41.5ºC, coughing, lack of appetite) the facility was locked and the possibility to get in from outside was the only used (Figure 2).

All the animals in this room immediately were treated with tetracycline in the water for 7 consecutive days. Immediately extra biosecurity conditions (different stockperson, separate shower facility, clothes and boots) were introduced into the farm. After the clinical signs declined and antibiotic withdrawn, all the animals from this room were slaughtered.

Diagnostic

Based on clinical picture (high fever, coughing, lack of appetite) the treatment with tetracycline, in the water, was introduced right away. Diagnostics started after the clinical signs declined and antibiotic withdrawn. It needs to be underlined that there were no deaths. All the animals were sent to slaughterhouse. Slaughter checks were performed and tonsils from 15 randomly selected pigs with lung lesions were taken for PCR. The affected lung tissues were submitted to the laboratory for App culture.

Procedure

The empty pens were first fumigated with a disinfectant with virucidal, bactericidal, fungicidal and sporicidal action and left for 5 days. The floor was soaked with a glutaryl aldehyde based disinfectant and left until completely dried. The objective of that procedure was to limit the infection level as much as possible before cleaning (minimizing the dust level). After 5 days the entire facility was cleaned, washed, disinfected, dried and left for 30 days before new pigs were introduced. The pigs from the other 3 rooms were observed clinically and were given tetracycline in the water for 7 consecutive days as prevention. From every pen 15 randomly selected pigs were bled for serology. During the next 8 weeks all the animals from the first building were gradually slaughtered. Tonsils from 5 randomly selected pigs / pen were taken for PCR. In the meantime many biosecurity precautions were undertaken to protect the sow building from contamination such as different stockperson, separate boots and clothes. Ten sentinels naïve for App were introduced into the breeding sector of the farm allowing them to have contact nose to nose with the local pigs. All sentinels were tested serologically twice: 1 and 2 months after introduction. After two months from infection, the blood from 45 randomly selected sows was taken for serology. For detection of antibodies against App serotype 2, a LC-LPS ELISA was used (Swine-Check).

Laboratory Results

App serotype 2 infection was confirmed by culture from lung lesions of pigs from the outer perimeter room. Pigs from this facility were sick showing typical clinical signs of pleuropneumonia. Slaughtercheck revealed typical lesions of App infection (abscess-like nodules present in the diaphragmatic lobes) in 35 of 52 pigs. Two hundred and seventy pigs from the other three rooms gradually slaughtered did not show any lung lesions. The serology carried out in randomly selected pigs from every room revealed that all the results were negative for App serotype 2. In total 90 pigs were bled for serological investigations. No clinical signs of respiratory problems were observed in sows and weaning pigs as well as sentinel animals. Serological investigations performed on 45 randomly selected sows shown all of them to be negative for App serotype 2. Tonsils of 15 pigs from the infected room were tested PCR positive. Tonsils of pigs from the other three rooms of the building were tested PCR negative. Sentinel pigs were tested serologically negative for App serotype 2 either 4 or 8 weeks upon introduction.

Conclusions

Results obtained clearly show that App infects naïve pigs if there is direct contact with contaminated material. In this particular case the source of infection there was very likely the stockman (fomites) attending the loading process.This person has been hired temporarily to help in the loading process. On a daily basis he was working on his own backyard farm nearby with a very conventional health status of pigs. Unfortunately, he was accepted to help but without any biosecurity conditions to be met. He simply came to help loading with the same clothes and boots he used to work with its own pigs. There was no permanent loading bay available and pigs were loaded using a movable ramp. Only the pigs in the outer perimeter room became infected with App serotype 2, of course the loaded animals get infected as well. It is worth noting that infection did not spread across the entire building. The swift actions undertaken upon the first signs of infection appeared, allowed to protect pigs from all the other rooms of this building, and also the other buildings (including sow buildings) from the App infection.

This case confirms the previous observations that airborne transmission of App is possible but limited. It also highlights the importance of biosecurity measures and training for everybody coming into a farm, and secondly the relevance of a good daily observation of the animals, and excellent communication between farm staff and veterinarians that allowed the fast and effective implementation of measures to contain the infection and to eliminate it before spreading into the whole farm.