Animal accommodations and ventilation systems are meant to control the environment of the pigs and to provide optimal conditions for growth and reproduction. However, the environment is never better than the system and how it is managed. Breakdowns and lack of maintenance are rather the rule than the exception. Poor design or failure in design of the ventilation system is also typical. The consequence of errors such as these may be poorer production or disease provoked by the stress of sudden drops or increases in temperature or draughts. Since we keep pigs under intensive conditions – they do not have many options for escaping from a sudden change in environmental conditions.

Tail biting and dirty pens

Tail biting is a typical non-specific reaction to a deterioration of the environmental conditions. It might be catalyzed by multiple factors, but high air velocity in the pen area due to ventilation failure is one of the causes most frequently associated with this disorder.

High activity during normal sleeping and resting periods and “clean tails” are early signs of an environmental problem. Moreover, pen fouling and dirty floors are usually associated with air currents in the lying zone, which get pigs to change their lying and defecation area continually. The latter condition may also be caused by overstocking and a too hot environment and in that case pigs simply wallow in their own faeces and urine to remove excessive heat from the body.

Risk of draughts is higher during the spring and autumn when outside temperature changes considerably from night to day. During the day temperatures might be high and the ventilation requirement increases. However, after sunset the outside temperature might drop significantly while the indoor temperature remains high from the heat built up in the construction during the daytime. Therefore, the ventilation system maintains a high ventilation rate. Unless the system is properly regulated, i.e., is fitted with outside temperature sensors and automatically adjusted inlets, which prevent the cool air from being directed toward the pigs lying area – there is a high risk of draughts.

Preventive measures of ventilation problems

The most important criteria for a properly working ventilation system is that inlets and exhaust fans be automatically regulated via a common control unit with temperature sensors attached (Figure 1).

Inlets are connected via wires to an electric motor, which opens and closes all inlets simultaneously according to temperature settings. The control system is designed to increase fan speed to create a negative pressure before the inlets start opening. This assures that fresh air enters with a certain speed and mixes with the inside air before it reaches the animal zone. A high negative pressure during winter might only be maintained if the building is air tight. Leaks and improper insulation are probably the most common cause of ventilation problems during the cold season in older buildings. Moreover, air velocity of the incoming air is more stable and air distribution better if the exhaust fan is provided with a baffle, which facilitates air flow rate within a narrow range.

|

Figure 1. Principle of ventilation system design with integrated exhaust fan, baffle, inlets and sensors. |

Errors might still occur if the inlet design is not made correctly. Thus, new inlets are designed with a curved slot, which directs the air toward the animals during hot weather and lifts the air during cold weather.

In addition, inlet slots might be moved out of position while high pressure cleaning. Therefore, it is important to check slot position and wires after emptying each unit.

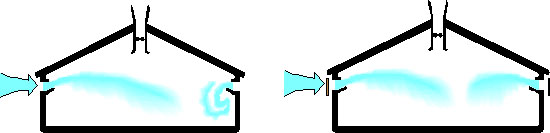

Figure 2. Ventilation inlets are opened too much and the air speed is to low to get the cooler outside air mixed with the inside air before it reaches the animals providing a draughty environment.

A typical problem in windy areas is that the wind pressure is higher on one side of the building than on the other. The result is that almost all ventilation air is supplied via the inlets on the wind side and in the worst case exhausted on the opposite side of the building. The only way of correcting this problem is to install a baffle along the side of the building, which will neutralize the static pressure of the wind.

Figure 3. Effect of static wind pressure on air movement and correction of problem via baffle along side of building.

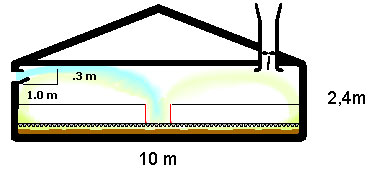

A common mistake while installing a ventilation system in a building is that air physics is not considered. Thus, when air enters through an inlet it spreads in a plume-formed shape and loses velocity as it moves while mixing with the inside air. Therefore, more and more space is required the further the ventilation air enters the room as shown in Figure 4. For each meter that the air enters 30 cm of free space must be available. This means that in a building 10 metre wide, with a 2.4 metre ceiling height and 1 metre high pen partitions the air will only penetrate the first 1.4/0.3 ~ 5 meter before it reaches the floor or slurry surface. Thus, the other side of the building will be poorly ventilated. The cheapest solution is to provide inlets in each side of the building.

Figure 4. 30 cm of free space is required for each meter of air entrance to ensure proper ventilation.