A previous article demonstrated the need to control the live weight (LW) dispersion generated during the production cycle, as well as the most important implications registered at the end of fattening and affecting production efficiency.

We will discuss strictly production and management strategies in two consecutive articles, aimed at reducing LW variability in piglets at, and at the end of, nursery. This first article addresses issues such as the segregation of animals and environmental comfort. The next one will discuss feeding and feeding trough space.

Even though healthcare is not discussed in these articles, we must not forget its importance. In order to control the emergence of new pathogens and/or recirculation of the existing ones, following the external and internal biosecurity rules and, on the other hand, carrying out a strict depopulation is essential. The production system also plays a very important role, since a farrow-to-finish nursery it is not the same as a S2 in a "three-phase" system; health monitoring is often simplified or complicated in the latter depending on the number of origin farms, and piglets health status homogeneity.

The importance of good management in the farrowing quarters

A good weight and homogeneity among piglets at weaning, or, in other words, at the beginning of the nursery phase, is essential, it being the starting point. What happens during lactation, in the farrowing quarters, is of great importance, and the possible factors to consider at an early age, include:

- Sows' genetics. Particularly relevant in the case of hyperprolific sows that farrow more piglets, generally somewhat smaller and with more weight dispersion.

- Segregation of gilts from the rest of the herd; some studies suggest that gilts piglets grow better if they remain separate from piglets from multiparous sows. These piglets are immunologically less competent, and can be adversely affected when mixed with piglets from multiparous sows.

- Ensure that sows have enough to eat and drink so as not to limit their productive potential. This can lead to maximizing birth weights, key to improving weaning weight.

- "Age" factor in piglets, linked to the fact that if dispersion increases in the farrowing dates, age difference (and therefore size and heterogeneity of piglets in the batch) also increases.

- It is essential to ensure that the piglets take an early and adequate intake of colostrum.

- If adoptions take place, they must be done within 24 hours postpartum.

- Practising "creep-feeding" from 7-10 days in order to minimize the period of post-weaning anorexia (especially in long lactations of 28 days or more.)

- If milk production is insufficient, supplement with a milk replacer: Some studies suggest an increased weaning weight and litter homogeneity using this strategy with the smallest piglets (Figure 1.)

Figure 1. Piglets on a milk replacer diet. Photo courtesy of Antonio Caballero.

The interest of segregating piglets by weight at weaning

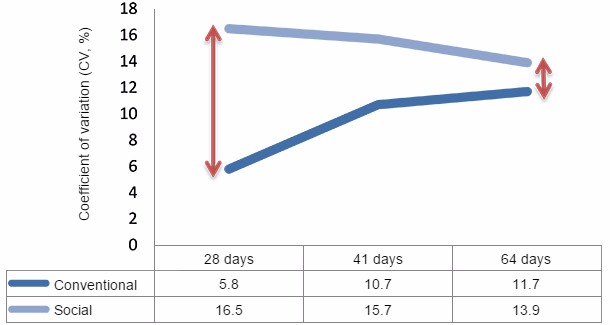

The aim of segregating piglets at weaning according to their LW is primarily reducing LW variability within nursery groups, hoping that it will remain fairly regular. Nevertheless, according to our own results (Jordà et al., 2015), the reduction of the coefficient of variation (CV) for the batch achieved at the beginning of the nursery period, subsequently increases to values similar to those obtained without segregating the animals. Thus, in Figure 2, the evolution of the CV during the nursery period is compared within two groups of animals: in one of them, the piglets were segregated by weight at weaning (conventional), and in the other one, an early socialization strategy was implemented and entire litters were weaned (social) with no mixing of animals after weaning. There is no negative control (not socialized and not segregated) in this study, but other studies suggest that the effect would be very similar (the final CV would be similar to the one obtained with the conventional treatment.)

Variability in the nursery phase (28-64 days)

Figure 2. Despite the effort to segregate piglets at the beginning of the nursery period, the CV tends to increase to levels similar to piglets that have not been segregated (Jordà et. al, 2015).

Appropriate environment and comfort

An effective control of environmental conditions and density of animals in the pens is essential (Figures 3 and 4.) Farms that decide to replace classical genetics sows with hyperprolific sows offer a typical example. If weaning/nursery pens are not properly resized, density increases thus hindering the achievement of the production targets and also affecting the homogeneity of the batch. Equally, important variations in the number of sows weaned per week can occasionally lead to similar problems.

Figure 3. Nusery room with a good level of comfort (photo courtesy of Laia Blavi.)

Figure 4. Example of nursery pens with optimal density (photo courtesy of Antonio Caballero.)

Some features that ensure appropriate environment and comfort for the animals, and contribute to the homogeneity of LW in the batch include:

- Optimal density in the pens: 4-5 piglets / m2 (0.20-0.25 m2 / piglet)

- Controlled climate appropriate for the facilities: Relative humidity control plus a room temperature of around 30 °C on arrival, followed by a gradual reduction of 2 °C per week until reaching a temperature of 23 °C at the end of nursery. For this, besides a good thermal insulation of buildings / rooms, we must have a good control of ventilation in order to avoid "stuffed" rooms and to keep draughts under 0.15 m / s, as well as provide heating (preferably of the environmental type) when required.

- Ensuring access to water (clean, good-quality and in sufficient quantities). Recommended minimum flow = 0.5 to 1.0 l / min.

- Slatted floor (totally or partially) but preferably plastic.

To sum it all up, we can say that although the dispersion that has taken place at the farrowing quarters is decisive in the final dispersion in the finishing phase, we can apply a series of management —or related to production conditions— measures in the nursery phase that would allow us to partially correct this dispersion.