Many times we become surprised when we see the contents that come out of the pipes when we empty them out for the first time. This "image" corresponds to the residues of medications, dissolved salts and other solids carried in the water that precipitate and build up in the pipes. Dorr et al. (2009) concluded that:

- The soluble components react among themselves blocking the medication systems.

- Using pH modifiers affects the water-soluble antibacterial drug solution.

Table 1. Soluble drugs mixing (pairings) and observations during 24 hours. Source: Dorr PM, Madson M, Wayne S, et al. (2009).

| + Precipitate - No precipitate | ||||||

|---|---|---|---|---|---|---|

| Tetracycline | Oxitetracycline | Clortetracycline | Clortetracycline Sulfamethazine | Sulfamethazine | Tiamulin | |

| Acetylsalicylic acid | + | - | + | + | - | + |

| Sodium salicylate | - | + | - | + | - | - |

| Amoxicillin | - | - | + | - | - | - |

| Trimetroprim Sulfamethoxazole | + | - | + | + | - | - |

| Penicillin G potassium | + | + | - | + | - | + |

| Neomycin 1 | - | - | - | - | + | - |

| Neomycin 2 | - | - | - | - | + | - |

| Tetracycline | - | - | - | - | + | - |

| Oxitetracycline | - | - | - | - | + | - |

| Clortetracycline | - | - | - | - | + | - |

| Clortetracycline Sulfamethazine | - | - | - | - | + | - |

During the emptying of the building for its cleaning and disinfection before another batch of pigs is introduced, and when medicating the water, we will have to control the critical points of the system in order to maintain the biosecurity of this nutrient in the farm. Apart from the drinkability of the water, we must control four basic points:

- Continuous supply

- True intake

- Clean and disinfected pipes

- Design and maintenance of the installations

A correct protocol allows the installations to be maintained in a perfect state for their use, along with keeping them clean and disinfected.

1. The installation:

The goal is to control the critical points in the installations:

2. Cleaning:

The design of the tanks and the pipes must allow for its complete drainage.

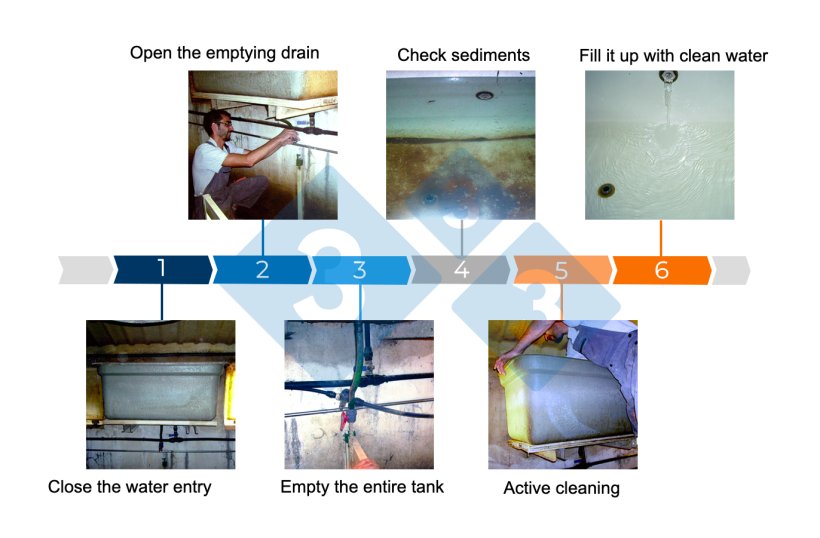

2.1. Tank:

- Upper lid for preventing the entry of dirt.

- Filter at the entry point in order to avoid sedimentations.

- Lower drain in order to facilitate the emptying.

- Flexible pipe in order to ensure water entry through the upper area and to reduce the possibility of the entry of mud.

- Level control (water-level buoy).

- Slope smaller than 1:20.

- Close the entry coming from the general tank.

- Draining or “flushing” at a high pressure through each pipe until the water comes out completely clean. We need a “by pass” so the filter does not reduce the pressure.

- If dirt is very obvious, we will have to flood the pipes with a cleaning-descaling solution. This solution must remain during the time recommended by the manufacturer (12- 24 h) so it can do its job.

- Draining and rinsing. Verify the absence of cleaning solution residues.

- Open the drinking water influent of the general tank.

The filter is an essential element for maintaining the pipes system clean.

Check the filters

- They must prevent the entry of light to avoid the growth of algae.

- The use of filters with disposable cartridges is not recommended (there is the risk of running out of spare cartridges or stocks).

- The cleaning of the filters will have to be carried out when necessary (depending on the quality of the water and the frequency of the medications).

Cleaning the pipes and checking the flow

3. Disinfection

3.1. The sanitizer:

In order to choose one we must bear in mind:

- The bactericide spectrum.

- Neutrality against the physical-chemical changes of the water (especially pH).

- Efficacy against the biofilm.

The Royal Decree RD140/2003 bears in mind the use of other products besides chlorine. Chlorine is widely used due to its high availability and its low cost, but it has a series of disadvantages, because it increases the water pH boosting precipitations, and it interferes with the good solubility of some drugs (sometimes it is recommendable not to chlorinate water during the treatments with antibiotics). The behaviour of the chlorine against the biofilm is uncertain and its spectrum is incomplete. Nowadays other products are taken into consideration in order to sanitize the water, and their features are evaluated in the following table.

Table 2. Features of water sanitizers. Source: CEVA Salud Animal.

| Stabilized peroxides | Chlorinated compounds | Organic acids | Iodized compounds | |

|---|---|---|---|---|

| Spectrum | +++ | ++ | ++ | ++ |

| Corrosion of materials | - | + | + | + |

| Toxicity | - | + | + | + |

| Irritant | - | ++ | ++ | + |

| Harmful action on rubbers and plastics | - | - | ++ | - |

| Efficacy against organic matter | +++ | - | + | + |

| Speed of action | +++ | ++ | ++ | ++ |

| Favoring of biofilm | - | + | + | + |

We can also consider ozone, UV light, or filtration which have a much better efficacy, but their cost is higher. Hydrogen peroxide (H2O2) is gaining in popularity as a sanitizer and it has very interesting features (see table).

3.2. Sanitizing via the dosing pump:

It is not recommendable to use drug dispensers, because they work at a very high dosing level and this obliges us to make very high and continuous dilutions. Also, the sanitizers can harm their membranes.

The water sanitizer dosing pumps are electrical devices that inject a certain amount of liquid inside a pipe or a tank, and we can adjust them. They work on the basis of a nominal flow rate (maximum %) and at a certain pressure. The most common ones work at a maximum flow rate of 3 liters/hour and at a pressure of 7 bars. There are two main kinds:

- Constant dosing: Nominal flow rate (0%-100%). We must know the water flow rate (liters/hour) to be treated in order to adjust it. Its running is automatic and we have the possibility of setting up a timer.

- Proportional dosing: Flow rate proportional to the signal facilitated by a meter that emits pulses, injecting only according to the flow rate that circulates through the pipe. This system is much more precise.

4. The importance of maintaining the entire medication system clean

A study examined the exposure of water-soluble drugs to other products (pH modifiers, acids, and others) normally administered through the water. The results of this study underline the importance of maintaining the entire drug administering system (tanks, dispensers, pipes, etc.) clean. For instance, the addition of citric acid and ammonia for the modification of the pH caused reactions and residues in 9 out of the 15 drugs that were evaluated.

Due to this, when substances are injected in the pipes with the aim of cleaning and disinfecting them as, for instance, sodium hypoclorite, the sensible action is to clean with "fresh water" (“Flushing”) before administering any water-soluble therapeutic product. If we do not do it, residues can be produced and they could block the dispensers, pipes and drinkers.