Porcine reproductive and respiratory syndrome virus (PRRSv) is an important infectious agent in the swine industry worldwide (Neumann et al., 2005; NPB 2011; Nieuwenhuis et al., 2012). Thus, efforts are being made to better understand the source of PRRSv infections (Torremorell et al., 2004). It has been demonstrated that PRRSv survives for long periods of time in cold temperatures (Benfield et al., 1992; Bloemraad et al., 1994; Zimmerman et al., 2010), which makes it transmissible by indirect routes including transport trailers. Among all routes of PRRSv infection, transmission via transport was considered second in importance (Torremorell et al., 2004).

To prevent PRRSv infection via transport, different approaches have been documented to successfully inactivate the virus from trailer surfaces. These protocols are based on cleaning and power washing the trailer followed by one of the following:

- Completely drying the trailer for 8 hours (Dee et al., 2004a; Dee et al., 2004c; Dee et al., 2005a; Dee et al., 2005b);

- Disinfection of the trailer with 7% glutaraldehyde and 26% quaternary ammonium chloride product (Dee et al., 2004a; Dee et al., 2004c) Dee et al., 2005a);

- Thermo-assisted drying and decontamination (TADD), which consists of heating the trailer temperature to about 71ºC for 30 minutes followed by 2 hours of downtime (Dee et al., 2005b; Dee et al., 2007).

All these procedures appear to be efficient in inactivating PRRSv present in trailers, but they also have important drawbacks. First, significant investments are required to build effective truck washing stations. A washing station costs between $100,000 and $150,000 USD per bay. Variable costs have been reported to be as high as $ 450 per wash (Loula and Schwartz, personal communication, 2011). Additionally, lack of compliance to properly follow biosecurity standards has been described (Racicot and Wogalter, 1995; Racicot et al., 2011) which can lead to poor trailer washing/disinfection and survival of pathogens. Moreover, there is a risk of cross-contamination with PRRSv and other pathogens during the process of washing multiple trucks at the same time in the same washer facility.

As a result, it has been recently reported that about 50% of vehicles used for transporting pigs in the United States are not washed between loads (Schneider et al., 2011). Moreover, Bigras-Poulin et al. followed almost 400,000 pig movements and reported that a truck was used for more than one pig movement event nearly 80% of the times before being disinfected. In some situations, a specific truck was used more than 10 times before it was disinfected.

Therefore, we conducted a study to determine PRRSv-infectivity half-life in manure at 4, 20, 60 and 80°C. Standard laboratory methods were used to inoculate PRRSv in manure samples kept at designated temperatures and to test samples after successive points in time for virus infectivity. Regression models were created to estimate PRRSv half-life at each incubation temperature.

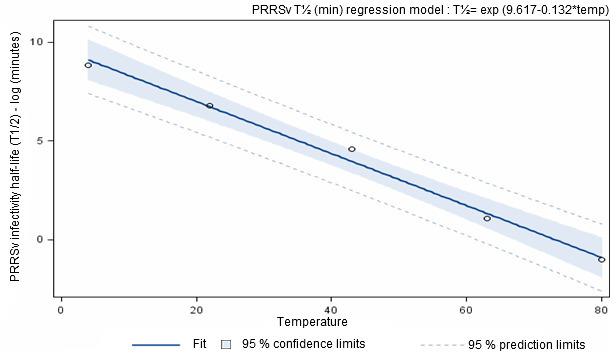

Figure 1 – PRRSv-infectivity half-life in manure environments.

X-axes are temperature in ºC and Y-axes are log10 of time in minutes. The solid line is the slope of the linear regression model of half-life in minutes in the log-scale. The bands around the solid line represent 95% confidence interval of the T ½ means (open circles). The dotted lines are the 95% prediction limits of the model. The regression model formula for PRRSv-infectivity half-life in manure is T ½ = exp (9.617 – 0.132* temperature). This formula predicts PRRSv T½ in minutes given temperature in Celsius.

We observed an exponential decrease in PRRSv infectivity with increasing temperature (Table 1, Figure 1). In other words, PRRSv is inactivated significantly faster as temperature is increased.

Table 1. Median PRRSv infectious half-life at different ambient temperatures in manure.

| Temperature | T ½ in manure |

| 4.0 ºC | 112.6 hours (103.2, 123.8) |

| 22.0 ºC | 14.6 hours (12.6, 17.2) |

| 43.5 ºC | 1.6 hours (1.5, 1.7) |

| 63.0 ºC | 2.9 minutes (2.1, 4.4) |

| 80.0 ºC | 0.36 minutes (0.30, 0.45) |

Results of this study can be used as a basis for developing strategies to inactivate PRRSv present in manure-contaminated environments using heating treatments. For example, these data suggest a decrease of PRRSv from 106 TCID50/ml to less than 10-1 TCID50/ml in transport trailers can be obtained following heat treatment of 50 ºC for 7 hours, 40 ºC for 26 hours or 30 ºC for 96 hours.

The availability of cost-effective alternate methods to trailer washing and disinfection might decrease PRRSv regional dissemination via contaminated trailers. Although further experiments using full size trailers are needed to validate this model, this pilot study emphasizes that heat treatment is a valuable tool to inactivate PRRSv present in manure samples.