We visited the Coagra farm, located in the Spanish province of Lleida and owned by Jaume Alós. This family farm houses 400 danish genetics sows , working on a 3 week batch farrowing system. Weaning age is around 26 days. All fatteners produced are sent to different external finishing units.

The sow farm works with electronic feeding machines in gestation and farrowing. The gestating sows, after being pregnancy checked, are housed in a single 560 m² pen, forming a dynamic group. Currently, this pen holds five ESF (electronic sow feeding) stations and houses an average of 200 sows.

Taking advantage of the fact that the sows are in a large group, the following were added to the system:

- A scale to find the exact weight of each female and adjust her feeding curve.

- A heat detection station to identify females that return to estrus and gilts in heat. A boar is permanently housed in this pen. The system records how often females come to visit the boar to determine which sows are in heat.

- Separator to segregate specific sows in a pen, such as sows that are due to farrow, sows to be vaccinated, as well as animals that have lost their ID or females that the system has detected to be in estrus and must be inseminated.

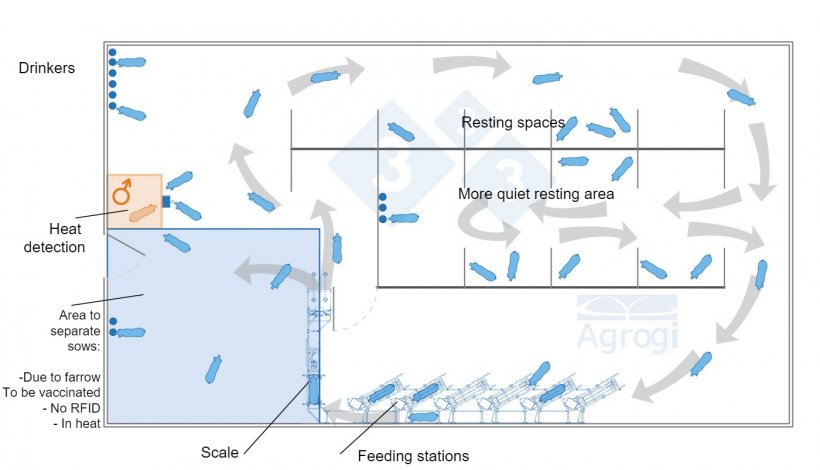

Pen layout and sow flow

Jaume Alòs stresses the importance of good design, both in regards to the circuit that the animals must make and the definition of the different areas.

The installations must meet the following objectives:

- Sows that want to re-enter the feeding area must go around the whole pen to avoid disturbing the sows that are about to enter. This reduces stress in the area near the entrance to the machines.

- The sows must pass through the heat detection station upon leaving the feeding station.

- There should be plenty of resting areas delimited by panels, some of those should be outside the areas of highest activity, such as the area in front of the feeding stations or the general sow passing areas.

A small detail that makes it much easier to check on the animals is the fact that the panels that make up the side of the resting areas are cut at mid-height. This still allows the animal to feel sheltered when lying against the wall, but it also makes it much easier to check on the females.

Jaume observes that by having a larger area, the sows have the option to - and in fact do - use different areas depending on the zones that provide them with the greatest comfort according to temperature, air currents, etc. This larger space also proves to be very useful in reducing confrontation when establishing the order of hierarchy.

Dynamic group gestation with weight monitoring.

Early introduction of gilts into the dynamic group

The gilts come from an external source and enter every two months at a weight of 60 kg. The future breeding animals are trained in the use of the feed stations starting at 110 kg. Gilts are introduced into the general dynamic group before the first service when the gilts weigh approximately 140 kg. Their entry into this facility allows the weight of the gilts to be monitored to match the farm's target weight at service, which in this case was 160 kg, although this has increased recently, as it appears that a higher weight at first service has improved the number of piglets born. Gilts also have access to the heat detection station that reports how often they approach the boar, which greatly facilitates heat detection.

When incorporated into the general group, these gilts are spray-marked to facilitate easy identification within the group for closer monitoring. It should be noted that no signs of fighting are observed in the females, including these younger animals.

Main advantages observed

Improves the ratio of kg of sow feed to piglet weaned: Maintaining proper body condition throughout the reproductive cycle is much more efficient than trying to recover thin or excessively fat sows. This, coupled with mating gilts at the correct weight, has contributed to the farm maintaining its annual feed intake per sow/year at around 1200 kg while going from 29 to 35 piglets weaned/sow/year. Going from 41 kg of sow feed per weaned piglet to 35 kg, apart from the savings in feed costs, should remind us of the increasing importance of the proper formulation of breeding sow diets.

Improves gilt acclimation: The replacement females, after training with the machines and before mating, are introduced into the dynamic group with the adult sows. This is possible thanks to the good design of the facility with its different areas and providing sufficient space. This has improved gilt acclimation and therefore improved the sanitary problems that are sometimes observed in gilt litters.

Improves longevity: Sows that started their productive life with the weight monitoring and the electronic feeding system have improved their longevity by + 0.35 farrowings. This system made it possible to mate them at an optimal weight and to maintain an optimal weight in successive gestations and lactations.

This facility is designed for a future adaptation to the mate and release system, with the objective of introducing the sows on day 3 post-mating to a dynamic group that would have about 320 females connecting this building with an adjacent one, thus eliminating their stay in the stalls during early gestation.

This is an example of how the correct implementation of technology can reduce costs, improve production outcomes, animal welfare, and also the public image of the farm and the job satisfaction of those who work there. We are sure that Jaume Alòs will continue, not only implementing useful technology, but also making the most of it. We thank the Alòs family for their time and for being such excellent ambassadors for the swine industry.