Health continues to establish itself as one of the main differentiating factors for profitability in pig production companies. Diseases reduce the total number of weaned piglets, increase mortality, and deteriorate feed conversion rates, adding to increased health, logistical, and labor costs associated with managing the situation. The difference in production costs between farms, production flows, or companies with significant health challenges and those less affected often exceeds the historical profit margin of the industry. This means that in less favorable market conditions, the profitability and economic sustainability of certain farms, flows, or companies may be at serious risk. Furthermore, the use of antibiotics to treat accumulated diseases in pig populations is increasingly restricted.

The foundations of a comprehensive health improvement program in a pig production system include:

- Prevention (biosecurity) to minimize the risk of introducing infectious agents

- Stabilization (control) to mitigate the impact of existing diseases

- Eradication of pathogens that can be eliminated at a reasonable cost

To achieve this, veterinarians and producers have several health interventions available, such as biosecurity, immunizations, strategic medication, all-in/all-out flow, batch farrowing management, herd closure, and acclimatization of replacement animals, which should be applied according to the specific context.

Diseases such as PRRS, swine influenza, enzootic pneumonia (Mycoplasma hyopneumoniae), or swine dysentery (Brachyspira hyodysenteriae) can often be eliminated through a proper combination of the aforementioned strategies. However, other high pathogenic strains of agents—such as Actinobacillus pleuropneumoniae, Streptococcus suis, Glaesserella parasuis, or Escherichia coli—cannot be eradicated from pig populations without resorting to more radical strategies such as depopulation–repopulation or cesarean derived-colostrum deprived piglet generation.

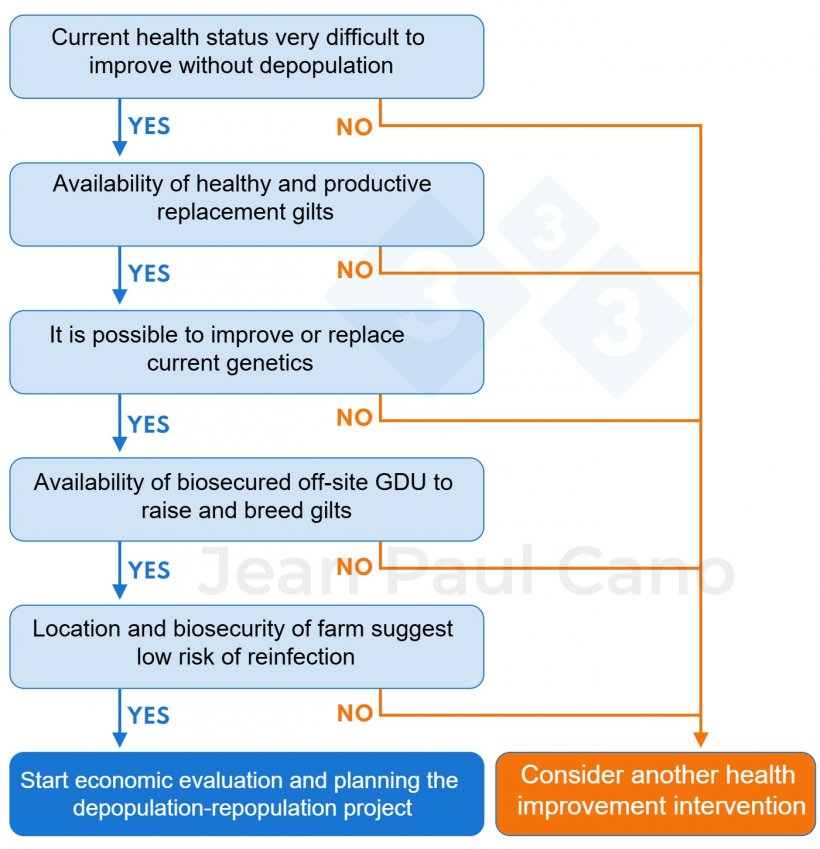

When one or more of these more resilient agents cause significant losses, or when several high-impact diseases coexist, a systematic analysis should be conducted to determine whether depopulation–repopulation is the most appropriate tool to implement.

Figure 1. Decision tree to assess the feasibility of carrying out a depopulation–repopulation project. Is depopulation-repopulation of interest to my farm?

Planning

Depopulation and repopulation of pig farms involve the complete removal of existing animals, followed by thorough washing and disinfection of the facilities, and the subsequent introduction of animals with higher health status. The experience gathered from 30 depopulation–repopulation projects can be summarized in five critical points that determine the success of the process:

- Decision-making process to justify and execute the project. This phase requires thorough research and a structured deliberation process to build consensus among management, production, and health teams before initiating the project. Key aspects to consider include:

- Estimating the current economic impact of present diseases, or projecting cost reductions after achieving the desired health status.

- Evaluating the risk of reintroducing the pathogens targeted for elimination or estimating the duration for which the improved health status can be maintained. Most economically important pathogens such as Brachyspira hyodysenteriae, Actinobacillus pleuropneumoniae, Streptococcus suis or Glaesserella parasuis can be prevented with a basic biosecurity program. Even in farms located in high pig density areas, because the indirect transmission of those agents is less likely.

- Ensuring the availability of replacement gilts—both initially and in the future—that meet the required health status and possess competitive genetic potential.

- Assessing the practical feasibility of the project, considering the availability of qualified personnel, suitable facilities, and sufficient logistical support.

- Source of replacement animals with superior health status. The company must have solid guarantees regarding the health status of the source farm for the replacement gilts. This farm must be free from high-impact epidemic agents such as PRRS, Actinobacillus pleuropneumoniae, Mycoplasma hyopneumoniae, and Brachyspira hyodysenteriae. In addition, the diversity and clinical impact of endemic agents such as Streptococcus suis, Glaesserella parasuis, Escherichia coli, or PCV2 must be thoroughly understood.

- Management of gilt development and breeding in an external facility. In the absence of an external facility for gilt development and breeding, a depopulation–repopulation project would involve a 20 to 22-week interruption in weaned piglet production, which in most cases renders the project economically unviable. To minimize this production loss, it is recommended to use a biosecure external facility to gather, race, and breed the replacement gilts so they are ready to enter the farm at the appropriate time (Fig. 2). This strategy can reduce the non-productive period to 4–6 weeks, a significant portion of which can be recovered thanks to the improved productive performance of the new animals.

Figure 2. Timeline and animal flow diagram during the depopulation–repopulation process.

- Procedure for emptying and decontaminating the facilities. Five or six weeks before beginning breeding at the external farm, breeding is halted at the farm that will be depopulated. From that point on, all weaned sows are sent to slaughter, and the process of emptying, cleaning, and disinfecting the farm begins, which will extend over the following 20 weeks. Weekly activity planning is essential to ensure the removal of 100% of organic matter from all areas, proper management of slurry pits, execution of necessary maintenance and renovations, pest control, cleaning of showers, storage areas, office, and surroundings of the farm, as well as systematic inspection of each section. Each company may have specific protocols for cleaning, degreasing, and disinfecting, but success depends primarily on meticulous and consistent implementation at every stage of the project.

- Introduction and starting of the new population. Once the total removal of organic matter, dust, and biofilm has been verified, and the correct application of disinfectants at the indicated concentration confirmed, along with the absence of moisture in the facilities, the duration of the “sanitary down time” becomes a less critical factor for the success of the project. In some cases, the use of sentinel animals is justified to validate the absence of infectious agents before introducing the new population. After an investment of this magnitude, it is crucial to ensure that the transport units used pose minimal sanitary risk. The entry of the sows should be staggered, starting with those closest to breeding or farrowing, and ending with the last sows bred at the external rearing facility, in order to facilitate embryo implantation. To ensure successful production in the new population, it is essential to consider training the sows on the automatic feeding system during gestation, as well as careful management of body condition during the external rearing phase.

Conclusion

Depopulation-repopulation is an effective strategy for breaking the cycles of high-impact disease transmission. Its proper implementation not only improves herd health status but also restores production efficiency and long-term profitability. However, the success of the process depends on rigorous planning, meticulous execution, and a prior technical-economic evaluation that justifies its feasibility. Faced with an increasingly challenging health environment and a more competitive market, establishing the most cost-effective strategy can make the difference between the sustainability or failure of a swine enterprise.