Onset of the problem

This is a 1,300-head sow farm in the Spanish province of Albacete that works under a 3-week batch farrowing system. The farm is quite isolated; the only nearby farms are a finishing barn and a nursery, which are integrated with the same company.

Vaccination against PRRS is done with a live vaccine, but there has never been an outbreak, and the flow of piglets is PRRS negative.

The farm raised its own replacement animals and had an internal genetic nucleus that had not received animals for several years until, at the end of 2014, a single entry of GrandParent gilts was introduced directly to the farm to update the genetics. In theory, they were PRRS, Mycoplasma, and APP negative animals, but APP was not checked.

In September 2015, the first cases of APP appeared upon entry into the finishing barn and in the internal gilt rearing area. Serotype 9 /11 was isolated.

First control measures

As a first measure, antibiotic treatment with marbofloxacin was started in sows around farrowing, and shortly after, an autogenous vaccine (bacterin) was used. Once the autogenous vaccine administration was established, an attempt was made to stop antibiotic treatment. However, at the beginning of 2017, APP cases reappeared in the nursery and finishing, so antibiotic treatment was implemented again in the farrowing room.

Although eradication was not possible due to bacterial colonization in tonsils, in August 2017, an attempt was made to cut vertical transmission. This consisted of treating all sows, replacement animals, and piglets in the farrowing room with marbofloxacin (IM, at the dose recommended in the technical data sheet), which was repeated after five days. During the six months before the treatment, no internal replacement gilts had been retained on farm, which was supplemented with the entry of 400 replacement animals after the treatment.

Unfortunately, shortly thereafter, APP cases appeared in these 400 external replacement animals and in the nursery and finishing.

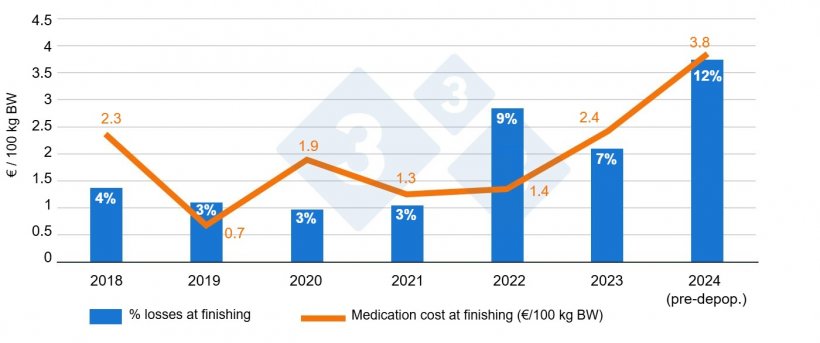

In 2018, the administration of the autogenous vaccine and marbofloxacin treatment of sows in the farrowing room was implemented again. The situation was kept under control for a while, but in 2022, losses in finishing skyrocketed. This made us consider depopulation as the only alternative to resolve the problem and reduce the consumption of antibiotics.

Figure 1. Annual comparison of % losses and medication costs per 100 kg Body Weight before and after depopulation-repopulation in finishing pigs

Depopulation-repopulation protocol

As a first step, future breeding female piglets were no longer kept on farm A calendar was established in which the last batch to be mated was set for June 2023, after which all weaned sows would go to the slaughterhouse. Therefore, the last weaning would be at the beginning of November.

To minimize productive losses, the gilts destined for the repopulation would be mated off the farm and enter at the end of December, so the farm could remain completely empty for a month and a half. During this time, all the facilities, including the slurry pits, would be thoroughly cleaned and disinfected. A special effort would be made to eliminate rodents, and any leftover feed on the farm would be removed.

The 3-week batch structure was continued. The last batch mated on farm, before the farm got empty was at week 24, and the first batch to be mated (off-farm) was at week 37. Therefore, the batches not mated were those from weeks 27, 30, 33, and 36, which is equivalent to a lack of production of 3.5 batches, which out of the total of 17 batches per year represented a 20% production loss.

Figure 2. Depopulation-repopulation program timeline.

A total of five batches were mated off-farm. This posed a significant logistical challenge, requiring the coordination of filling several Gilt Development Units (GDU) and performing estrus synchronization and batch matings in facilities not equipped for this purpose.

The farm was completely emptied on November 7, 2023, and the new animals entered on December 19, 2023.

After restocking, the farm stopped raising its own replacements that started coming from external GDUs

Results

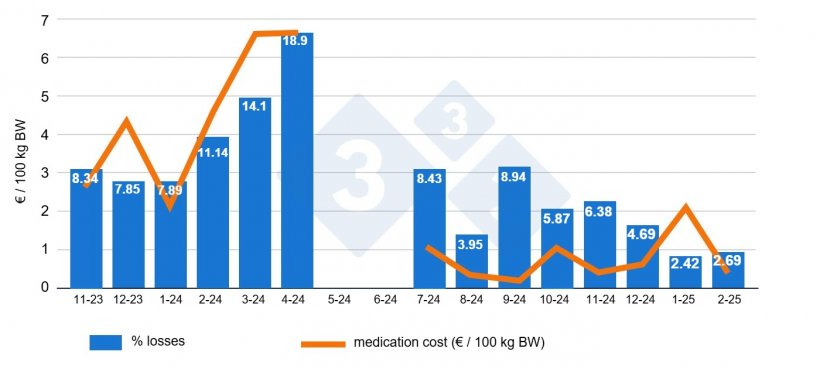

After the repopulation, no cases of APP have been detected again in any of the phases, and the animals remain negative by serology to this day. It should be noted that the depopulation was also used to eliminate PRRS and Mycoplasma from the farm.

Finishing: Mortality and antibiotic use

Following depopulation, the health of the first batches of finisher pigs was conditioned by the high incidence of ulcers and some lateral PRRS contamination. In addition, all piglets had been born to first-parity sows. Even so, there were considerably reduced losses compared to the last finishing batches before depopulation, and there was a spectacular reduction in the use of medications.

Figure 2. Monthly comparison of mortalities and medication expenditure per 100 kg BW before and after depopulation-repopulation in the finishing area.

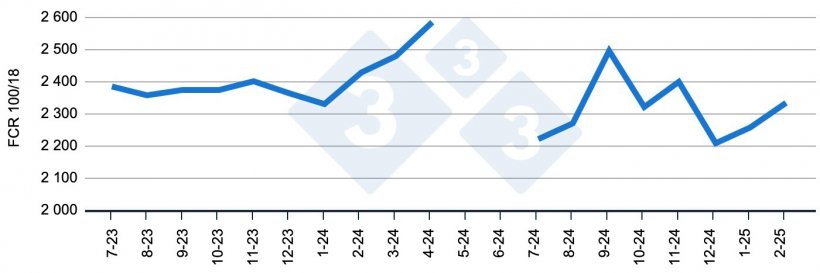

Figure 4. Evolution of the standardized feed conversion ratio between 18 and 100 kg.

The average feed conversion ratio (FCR) after depopulation was 2.302 (castrated Duroc), compared to 2.399 during the same period the previous year. This represents a savings of €3.50 per pig.

Sow farm: Evolution of antibiotic use

The use of antibiotics on the sow farm was drastically reduced, and the use of group B antibiotics was completely eliminated.

Treatments of lactating sows to control Actinobacillus pleuropneumoniae excretion were based on marbofloxacin (group B), as this antibiotic had been shown most effective. Other antibiotics, such as florfenicol (group C), were tried on several occasions, but the results were worse.

Table 1. Antibiotic consumption on the sow farm 2023 vs. 2024.

| 2023 | 2024 | ||||||

|---|---|---|---|---|---|---|---|

| Via | Cat | Index ESVAC* | % | Index ESVAC* | % | ||

| 0008 | Marbofloxacin | Injectable | B | 5.73 | 58.42% | 0.09 | 100% |

| 7034 | Amoxicillin Trihydrate | Oral | D | 2.21 | 22.58% | ||

| 7034 | Amoxicillin Trihydrate | Injectable | D | 0.5 | 5.13% | ||

| 7056 | Florfenicol | Injectable | C | 0.09 | 0.97% | ||

| 7125 | Doxycycline Hyclate | Oral | D | 1.27 | 12.90% | ||

| 9.81 | 100% | 0.09 | 100% | ||||

*ESVAC: European Surveillance of Veterinary Antimicrobial Consumption

In addition, successive antibiograms before the depopulation had shown a worrying reduction in sensitivity to various antibiotics.

| Latest analysis |

UG2070205-28/01/2020 |

UG1871522-02/10/2018 |

|||||||

|---|---|---|---|---|---|---|---|---|---|

| Cat. | Antibiotics | Method | MIC (mg/l) | Result | CML (mg/l) | Result | MIC (mg/l) | ||

| D | Sulfamethoxazole/trimethoprim. Sulfamid | MIC | 0.12 | Sensitive |  |

- | Sensitive | ≤ 0.12 |  |

| C | Florfenicol-Fenicol | MIC | 0.5 | Sensitive |  |

- | Sensitive | 0.25 |  |

| C | Thiamulna-Pleuromutilins | MIC | 16 | Sensitive |  |

- | Sensitive | 8 |  |

| C | Tildipirosin-Macrolides | MIC | 4 | Sensitive |  |

- | 4 |  |

|

| C | Tilmicosin-Macrolides | MIC | 8 | Sensitive |  |

- | Sensitive | 8 |  |

| C | Tulatromycin-Macrolides | MIC | 32 | Sensitive |  |

- | 32 |  |

|

| B | Ceftiofur-Cefalosporins | MIC | ≤ 0.06 | Sensitive |  |

- | Sensitive | ≤ 0.06 |  |

| B | Enrofloxacin-Quinolones | MIC | 0.06 | Sensitive |  |

- | Sensitive | ≤ 0.03 |  |

| B | Marbofloxacin-Quinolones | MIC | ≤ 0.03 | Sensitive |  |

- | Sensitive | ≤ 0.03 |  |

Economic study

On the other hand, the economic cost of the depopulation is worth analyzing to determine the time it takes to recover the cost.

| INCOME | ||||

|---|---|---|---|---|

|

DEPOPULATION (second half of 2023) |

||||

| Sows | Sow weight (kg) | total kg | price € | TOTAL € |

| 1,300 | 215 | 279,500 | 1.04 | 290,680 |

| EXPENSES | ||||

| Cost of raising own replacements | ||||

| Age at mating | 7/9 months* | |||

| Weight at mating | 160 kg | |||

| TOTAL € | ||||

| Cost € gilt at mating | 260 | (x 1300) | 338,000 | |

| Cost until start of production | ||||

| Extra payment for external GDUs | 35,352 | |||

| Feed | - | |||

| Inputs for external matings | - | |||

| Extra labor | 2,000 | |||

| Production loss | ||||

| 3.5 batches | 71,500 | |||

| Total expenses | 446,852 | |||

| Expenses-Income | 156,172 | |||

The cost price criterion has been used to carry out this assessment. The expenses have taken the farm owner's loss of income into account, although the loss of opportunity (the profit from the sale of the piglets not produced) has not been evaluated.

Also not evaluated are the benefits, such as improved reputation and satisfaction in the finishing barns due to the change from very poor health to SPF (specific pathogen free).

The savings in the finishing phase resulted from three factors:

- Reduction of medication use = 2.5 euros

- Reduction of losses = 3.5 euros

- Improved FCR = 3.5 euros

The total savings in finishing was €9.5/pig produced.

With 33,000 pigs produced per year *€9.5 = €313,500.

The reduced cost of medication and vaccination in the sow farm was not included in this analysis.

A good measure is ROI (return on investment), i.e. how much money I get for the investment made.

| ROI = | (profit obtained - money invested) | = % |

| money invested |

| ROI for the first year would be: | (313,000-156,172) | = 1.007, i.e., an ROI of 100%. |

| 156,172 |

Expressed in time, the investment is recovered in six months.

Projects like this not only improve production costs but also represent a marked before and after, a resounding improvement in quality and production conditions, and a stimulus for all the people involved on the farm.