Importance of Air Quality in Buildings for Swine

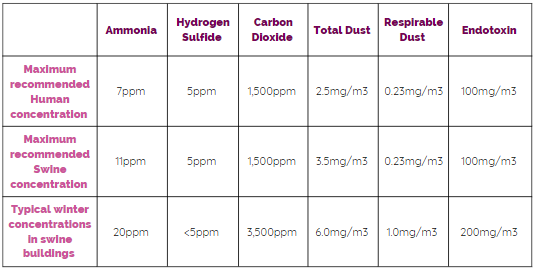

In order to guarantee the good health and wellbeing of pigs and staff alike, we need to pay attention to several pollutants which can have a negative impact on animal health and productivity. They also represent a risk for the workers in the barn. A summary of recommended maximum concentrations is given in Table 1 later in the article.

Carbon dioxide

Carbon dioxide (CO2) is produced and released by animals (and humans) as their body uses nutrients from the feed and oxygen from air. At low concentrations, carbon dioxide has low toxicity but it can negatively affect performance. In high concentrations the respiratory rate will be affected, and ultimately (with concentrations above 10%) the subjects can become unconscious and die. It is commonly recommended to increase ventilation if carbon dioxide level is above 0.3% (=3,000 ppm), however when the level goes below 2,000 ppm, ventilation is assumed to be excessive.

Ammonia

Ammonia (NH3) comes from the nitrogen present in the urine and faeces produced by the animals present in the building. The building design can have an impact on ammonia levels, for example the concentration is higher in deep-pit slurry systems, with slats and mechanical ventilation. Nutrition also plays a role in ammonia levels, because a higher protein in feed means more nitrogen can be excreted (nitrogen is an essential component of amino acids, the constituents of protein). While it is agreed that excessive NH3 has a negative impact on growth and health of pigs, there isn't a clear agreement about which levels to target and for instance the EU regulation (Directive 91/630/EEC) does not establish a maximum level for ammonia. Some reports indicate that performance and health are affected with levels around 50 ppm, and that long exposure increases the risk of pneumonia and other respiratory diseases. It is also important to remember that ammonia is a concern as far as air pollution is concerned.

Hydrogen sulphide

Hydrogen sulphide (H2S) is a toxic gas, which is also a by-product of urine and faeces. Because this gas is heavier than air, when ventilation is not adequate, and especially in deep-pit slurry systems with slats and mechanical ventilation, the concentration will increase. However, it usually remains dissolved in the liquid effluents, so, until the effluent is agitated, there are no real toxicity concerns. For this reason, gas levels are usually not toxic (from 0.1 to 5 ppm), even if the typical rotten egg smell is detected. Symptoms like eye and respiratory irritation can be felt when levels increase at 10-20 ppm. It has been reported that such levels will create fear of light, loss of appetite, and nervousness in pigs. Farm workers need to understand that toxic levels (above 100 ppm = 0.01%) can be reached very fast when the slurry is agitated, resulting in paralysis of their sense of smell, which may give them the impression that they are safe. On the contrary, this is when they face serious risks because the gas affects their nervous and respiratory systems. Such levels can be fatal to both human and pigs.

Methane

Methane (CH4) is a normal by-product of decomposition of manure and is usually non-toxic. This gas is lighter than air, and can accumulate in poorly ventilated areas such as closed manure storage pits. High levels can cause headaches and ultimately asphyxiation, but the major concern with methane is that it is highly flammable and explosive when reaching levels above 20,000 ppm (2%). It is recommended to maintain methane levels below 500 ppm in swine buildings.

Carbon monoxide

Carbon monoxide (chemical formula CO) is a colourless, doorless, and tasteless, flammable gas. A bit less dense than air, it is not a direct result of pigs activity, but can be produced by heating systems which are not functioning properly. High levels of carbon monoxide are toxic to both human and pigs. At moderate levels (above 160 ppm) carbon monoxide can lead to increased number of stillborn piglets and reduce vigour and growth performance.

Dust particles

Fine dust or particles can cause respiratory issues, for both humans and pigs. Feed and dry manure are obvious sources of dust and they can carry toxic substances such as ammonia, but also viruses, bacteria or antibiotics. Inhalation of dust particles can result in different diseases such as bronchitis, asthma, sinusitis, usually associated with non-specific symptoms (fever, headache, fatigue, muscle pain) or allergic reactions.

The importance of proper ventilation

In order to remove toxic gases, contaminants and moisture, but also to provide fresh air and appropriate temperature, making sure that staff and animals are healthy and that performance is maximised, at an affordable cost, a proper and adequate ventilation is essential. Making the ventilation system working properly is not an easy task, as there are lots of factors involved, such as the type of ventilation system, insulation and design of the barn, targeted temperature vs. outside temperature, air circulation outside (wind) and of course, the number, weight and age of animals. This requires a good understanding of how air moves and it is advised to get proper training or advice. Routine maintenance of the ventilation system and cleaning are very important.

Table 1: Recommended maximum concentrations of toxic dust and gases in swine confinement buildings (Source: U.S. Pork Center of Excellence)

Contact:

Contact us using the following form.