Checklist for a porcine semen processing center

A checklist for a semen processing center is a document that outlines the steps involved in producing a semen dose. It serves as a tool to ensure consistency, traceability, and quality throughout the entire process. Detecting and correcting errors during semen processing is crucial for maintaining safety and fertility outcomes on the farm. Traceability and systematic monitoring are key to the success of any seminal production program.

To create an effective checklist for semen production, it's essential to:

- Identify all critical control points

- Organize them logically

- Test the checklist to ensure it functions effectively in practice

Purpose of the checklist

A well-designed checklist:

- Ensures consistent quality control

- Facilitates process traceability

- Streamlines the identification of problems and corrective actions

- Standardizes procedures

- Serves as a guide and training tool for new operators

How to design a checklist

Start by:

- Defining your operational standards

- Implementing rigorous quality control steps

- Committing to continuous process improvement

To do this effectively:

- Understand every step of the semen production process

- Use only high-quality materials

- Monitor key semen parameters that define quality

- Enforce strict biosecurity and hygiene protocols

What should a checklist include?

The length and detail of the checklist will depend on your specific operational requirements, but it should include at a minimum:

- The goal or purpose of the process

- Each process step in logical order

- A description of what needs to be checked

- The criteria for acceptance

- Detailed instructions where needed

- Space for observations or deviations

- Signatures and dates of verification

Where to begin? Core areas of focus

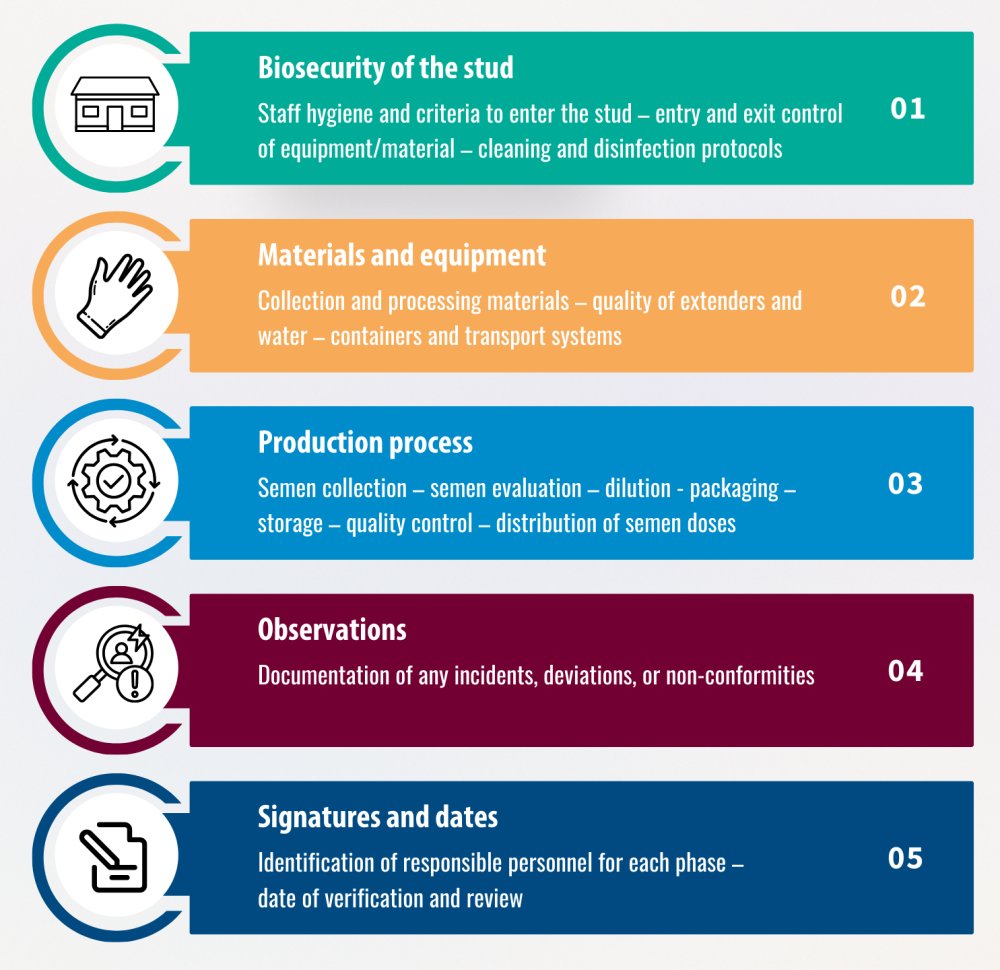

A comprehensive checklist should include at least the following five sections. Each can be expanded based on your specific needs:

1. Biosecurity of the stud

- Staff hygiene and criteria to enter the stud

- Entry and exit control of equipment/material

- Cleaning and disinfection protocols

2. Materials and equipment

- Collection and processing materials (e.g., gloves, semen bags)

- Quality of extenders and water

- Containers and transport systems

3. Production process

- Semen collection

- Semen evaluation

- Dilution

- Packaging

- Storage

- Quality control

- Distribution of semen doses

4. Observations

Documentation of any incidents, deviations, or non-conformities

5. Signatures and dates

• Identification of responsible personnel for each phase

• Date of verification and review

Critical points to emphasize in the checklist

Certain steps and materials are particularly sensitive and must be carefully controlled.

These critical control points include:

- Disposable materials (gloves, bags, semen container like tubes or bags):

Must be certified as sperm-safe and free from toxic substances. - Boar preparation and semen collection:

Assess boar condition (nutrition, body condition, health status). Ensure proper collection technique to avoid contamination from preputial secretions or external substances (e.g., detergents, water). All collection materials should be at body temperature. Proper collection is key to ejaculate quality. - Transport and protection of ejaculate:

Maintain ejaculate at controlled temperature (~35°C) immediately after collection to prevent thermal shock and preserve viability. - Laboratory procedures:

Ensure all equipment (microscopes, heating stages, distillers, etc.) is clean, calibrated, and at the appropriate temperature for use. Use disposable materials where possible. Accurate assessment of semen is crucial for the subsequent stages of production. - Extender preparation and handling:

Prepare and store extenders correctly (powder at ~17°C, diluted extender at ~5°C). The ready-to use extender should be clear, particle-free, and prepared with high-quality water according to the recommendations of the semen extender supplier, as extender comprises ~90% of the semen dose. Maintain strict temperature management during dilution. The maximal temperature difference between semen and extender should not exceed ±1°C). - Packaging:

Ensure filling systems do not apply excessive mechanical forces that could damage spermatozoa. All materials used, must be clean. - Quality control:

Semen doses must meet established quality standards before release. This ensures dose viability and fertilization potential. - Storage of processed semen:

Temperature is key (critical) to guarantee the fertility of the doses. Quality control prior to distribution to the farm must be established as quality assurance.

products

Contact:

Contact us using the following form.