France's European-level commitment to reduce ammonia emissions by 15% by 2030 compared to 2005 forces pig industry players to consider new courses of action, both in existing facilities and in new construction projects. Temperature is one of the main factors that influences ammonia volatilization, along with pH. While slurry acidification has not been remarkably successful in the country due to various technical, economic, and even social constraints, acting on temperature is emerging as an avenue of interest.

Within the framework of a project financed by ADEME and PNDAR, IFIP has coordinated a study focused on two axes of temperature management in finishing barns: ambient temperature and slurry temperature.

Reducing the temperature of stored slurry: pit-bottom slurry cooling system vs. floating system

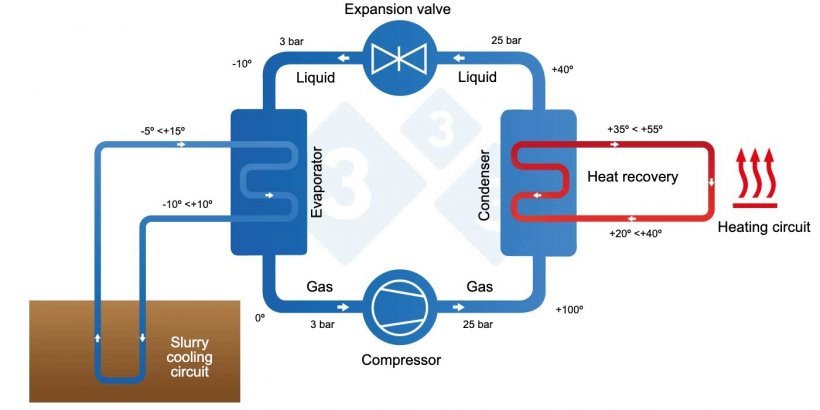

Part of the project has been dedicated to implementing systems aimed at reducing the temperature of the slurry stored in the under-slat pits of finishing pig barns. These slurry cooling systems consist of a network of pipes in contact with the stored slurry, which are connected to a heat pump and a calorie collection system. A heat transfer fluid circulates through this network, allowing the heat to be captured from the slurry and transferred to a storage and/or consumption system. The heat recovered from the slurry can be used, for example, to heat a hot water tank or to preheat the air in post-weaning or farrowing barns.

Schematic diagram of the workings of a slurry cooling system. Source: IFIP.

Two slurry cooling systems were installed in finishing rooms at IFIP's experimental station located in Romillé, France:

- The first system, "pit-bottom slurry cooling," had a network of tubes fixed to the bottom of the under-slat pit.

- The second, “floating slurry cooling”, had a pipe network attached to a floating platform on the slurry surface.

In both systems, the cooling capacity was 20 W/m2.

Pit-bottom slurry cooling system under experimental conditions. Source: IFIP.

Floating slurry cooling system under experimental conditions. Source: IFIP.

Four batches of finishing pigs were monitored, both for animal performance (average daily gain, feed conversion rate, carcass composition) and for environmental performance (ammonia, nitrous oxide and methane emissions, volume and composition of slurry produced). Temperature sensors were installed at various depths of the under-slat pit to measure the effect the type of cooling system had on the slurry temperature.

Parallel to monitoring the batches of pigs in the IFIP experimental station, measurements were also taken on a commercial farm equipped with a slurry cooling system at the bottom of the pit, with an installed cooling power of 10 W/m2. The monitoring protocol in this trial, conducted under commercial conditions, was practically identical to that followed under experimental conditions.

Methane reduction without affecting production yields

In experimental and on-farm conditions, no differences in finishing pig performance were observed between the different slurry cooling systems and the control rooms.

In the IFIP study, pit-bottom slurry cooling reduced the slurry temperature by 10°C under experimental conditions (only 2.5°C under real farm conditions), while surface cooling only achieved a 7°C reduction.

| Emission (kg N/C per space and year) | Experimental conditions | Farm conditions | |||

|---|---|---|---|---|---|

| Control room | Room with pit-bottom slurry cooling | Room with surface slurry cooling | Control room | Room with pit-bottom slurry cooling | |

| Ammonia | 2.2 ± 1.3 | 1.9 ± 1.4 | 2.3 ± 1.3 | 1.9 ± 0.9 | |

| Nitrous oxide | 0.08 ± 0.08 | 0.08 ± 0.08 | 0.09 ± 0.08 | nm | nm |

| Methane | 4.3 ± 2.9 | 1.8 ± 0.9 | 2.7 ± 1.2 | 13.0 ± 5.8 | 10.5 ± 5.1 |

nm : not measured

The gas emissions from the control rooms were considered representative after comparison with existing literature. In rooms equipped with slurry cooling systems, ammonia emissions were reduced by only 14% under experimental conditions, while no effect was measured under farm conditions. In the case of methane, the temperature reduction slowed the activity of methanogenic bacteria, resulting in a 59% reduction with pit-bottom cooling and a 38% reduction with surface cooling, both under experimental conditions. Under farm conditions, this reduction was only 19%.

The innovative nature of this study lies in its methane results, which other teams had not previously published. Slurry cooling is shown to be an effective tool for reducing methane emissions, while its effectiveness on ammonia has been lower than that indicated in the literature. This difference is explained by the installed cooling capacity: the reduction of ammonia is proportional to this capacity (10% per 10 W/m² installed). This ratio explains the lower efficiency observed in farm conditions (10 W/m² versus 20 W/m² in the experimental station).

Slurry cooling systems: A solution with potential and technical limits

Reducing the temperature of slurry is a promising approach to limit ammonia production on pig farms. Moreover, this technique offers an additional advantage related to energy recovery, representing a significant incentive for its development, especially in the context of increasing energy costs. However, adapting this technique to existing barns presents certain technical limitations, such as reducing the available volume in the under-slat pits.

Nadine Guingand, environmental engineer at the IFIP-Institut du porc.