Precision is the only future and prevention is the foundation of precision...

By Dennis DiPietre

We live a world which is undergoing significant change. Never in the history of life on the planet has there been more demand for the transformation of the Earth’s scarce raw materials into consumer goods for people around the globe.

The world is being reorganized to facilitate the globalization of both demand and production, so the desires of people next door and in the farthest reaches of the planet can be communicated in real time to the millions of production and distribution chains around the world standing ready to fulfill them. At the same time, those very production processes are being challenged with the problem of how to satisfy these inexhaustible wants utilizing a finite set of scarce global resources.

Agriculture at the center of change

There are three primary forces now converging to produce a tipping point in how modern and traditional agricultural businesses use scarce global resources to supply the rapidly evolving worldwide demand for food and other goods.

The next revolution is upon us

The first revolution in modern pork production occurred in the late 1980’s and the decade of the 1990’s until 1998. It was the implementation of scale to achieve dramatically increased output per unit of invested capital and therefore a much lower per unit cost of production. The next revolution will be a revolution in precision.

![]() It is no longer acceptable or possible to satisfy even near-term future demand simply by scaling up and producing larger volumes of output even at lower per unit cost. Resources are becoming more expensive as they become harder to locate, mine or produce. Governments are forcing costs which were formerly externalized to society back onto individual production systems. Higher and higher input costs will characterize production systems that try to manage future demand with high average output without precision methods. We are rapidly approaching a moment of truth with respect to global resources where satisfying the immensity and complexity of (future) global demand requires a focus beyond production systems based only on high average output to more precision based production processes that focuses on reducing system variation and dramatically improving efficiency while maintaining high output performance.he ability to shift with reasonable speed to a focus on precision technologies, espe- cially in meat animal production, will be the deciding factor in which companies gain access to the increasingly scarce global resources needed to produce meat profitably in this time of rising demand and input restrictions.PRECISION TECHNOLOGIES

It is no longer acceptable or possible to satisfy even near-term future demand simply by scaling up and producing larger volumes of output even at lower per unit cost. Resources are becoming more expensive as they become harder to locate, mine or produce. Governments are forcing costs which were formerly externalized to society back onto individual production systems. Higher and higher input costs will characterize production systems that try to manage future demand with high average output without precision methods. We are rapidly approaching a moment of truth with respect to global resources where satisfying the immensity and complexity of (future) global demand requires a focus beyond production systems based only on high average output to more precision based production processes that focuses on reducing system variation and dramatically improving efficiency while maintaining high output performance.he ability to shift with reasonable speed to a focus on precision technologies, espe- cially in meat animal production, will be the deciding factor in which companies gain access to the increasingly scarce global resources needed to produce meat profitably in this time of rising demand and input restrictions.PRECISION TECHNOLOGIES

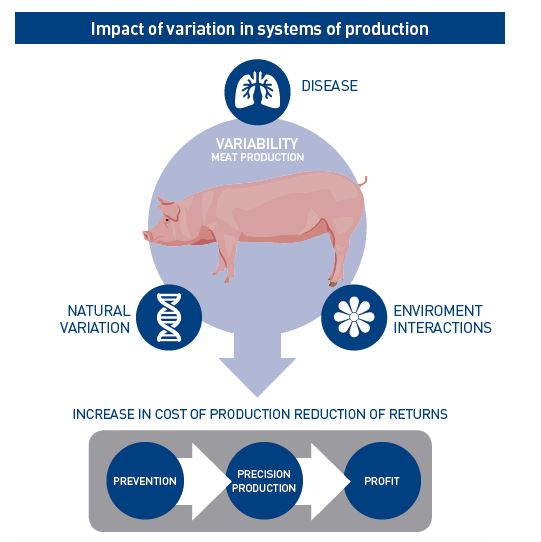

An understanding of precision technologies in meat production begins with the knowledge that biological production processes are naturally variable. The baseline level of variation in growth rate for instance, is in the broadest terms, a function of the genetic attributes of the animals combined with the production inputs and production system characteristics within which they are produced.

Though variation is natural, frequently, humans in all phases of production add to the natural variability of systems through their own interactions in the work environment. This is because many modern agricultural systems focus on attempting to optimize the “batch” rather than the individual animals which make up the “batch”.

"Mismanaged production environment added to the natural variation in a typical system make the farm’s production unprofitable, and only can be faced through precision production"

In a typical system, the production environment is optimized for the average animal and therefore nearly all animals are sub-optimized. An example is feeding a single feed diet to all animals in a building during late finishing when weights range over 50 kg from the smallest to the largest animals. These production systems are capable of high throughput but most do not measure many (or any key attributes) of work-in-process prior to sale of the finished product. No measuring means no correcting during the process when divergence from plan might be restored. This has led to a kind of blindness about the volume of waste in modern systems since current systems cannot measure it.

Poorly executed standard operating procedures, poor ventilation, inadequate nutrition, overcrowding etc. are examples of how the mismanaged production environment can add to natural variation. This increase in variation often substantially increases total cost of production as well as damages the final sales value of the farm’s production. That damage attacks profit from each end, increasing cost and reducing returns. The only way forward is through precision production.

Disease:the largest single cause of growth rate variation in finishing swine

Beyond the effect of the growing environment, it is widely asserted that disease is the sin- gle greatest source of preventable end product variation and quality diminution. Preven- tion can take many forms such as maintaining a high level of bio-security, careful cleaning and disinfection between building occupancies, bird and rodent control and vaccination to preemptively strike at profit damaging variation before it has a foothold.

The prevention of unnecessary variation is a complementary approach to investing in new technology for detecting emergent variation as it is happening and acting to reduce it before its damage is irreversible. The best part about prevention is that it is relatively low cost, very effective and it is available today. Prevention has several key advantages over the correction of problems after they appear, however, both will be required. Today, the extent of finishing variation in swine is often first discovered in the examination of comparative closeout metrics after the animals have been slaughtered and mitigation is long past as a possible strategy. Growth variation and its treatment is usually reserved to treating individual animals that are so damaged that they are not likely to produce anything but cull values. Wide variance in end weights is the hallmark outcome of many swine diseases but it is particularly true of PRRS infections and PRRS co-infections with SIV or mycoplasma hyopneumoniae. Precision is the future of all food production includ- ing pork and prevention is the foundation of precision.

Welcome to 333

Connect, share, and interact with the largest community of professionals in the swine industry.

Celebrating 137871Users on 333!

Sign upAlready a member?